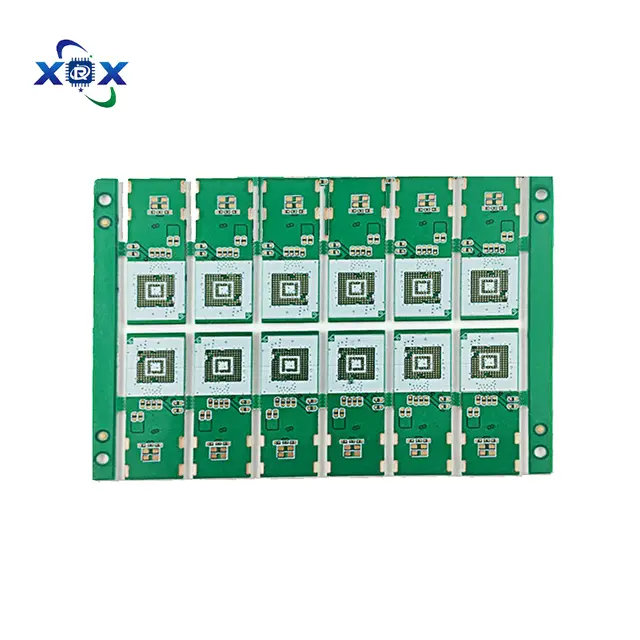

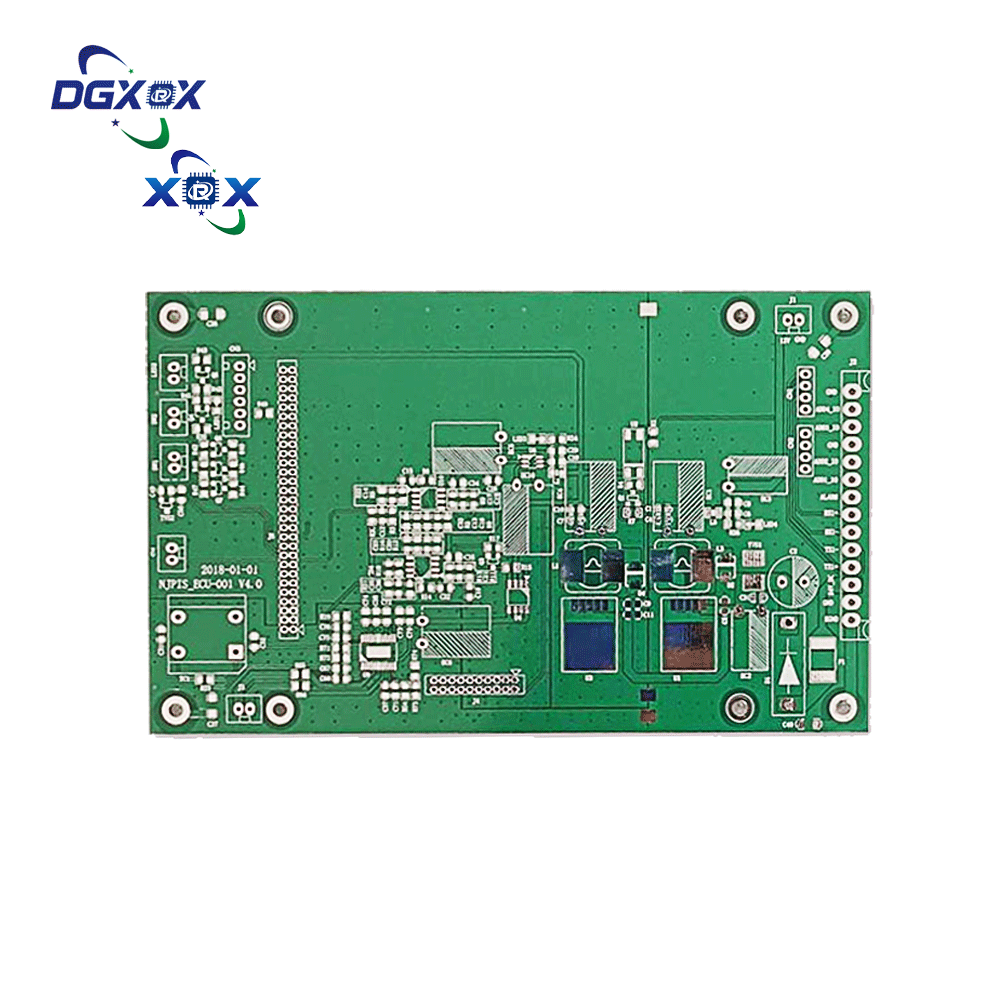

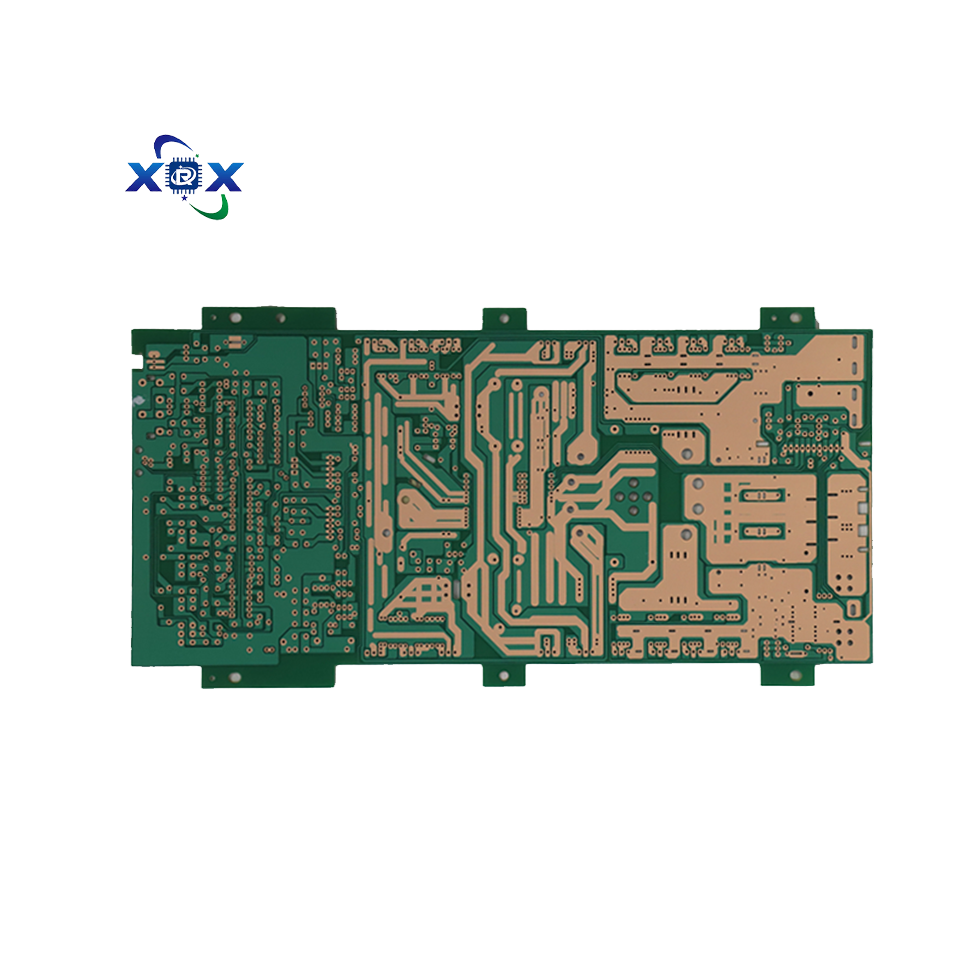

Single Sided PCB

At XingRongXing PCB, We manufacture custom single-sided PCBs using FR-4 and CEM-1 for cost-sensitive, reliable electronics. With clear DFM rules, fast prototyping, and consistent mass production, you get predictable quality, shorter lead times, and competitive pricing — all from one trusted source.

Key Advantages

Clear Capabilities

Min trace/space 6/6 mil, min drill 0.3 mm, 1–3 oz copper, 0.2–3.2 mm thickness.

Quality Assured

100% electrical test, RoHS compliance, full outgoing inspection.

On-Time Delivery

Samples in 3-5 days, volume in 10–15 days, expedite available.

From Prototype to Production

Stable process window, consistent lot-to-lot results.

Capabilities & Specifications

Applications

Single sided PCBs dominate in the following fields due to their low cost and high reliability:

Consumer Electronics

From smartphones to home appliances, our PCBs support the electronics you use daily. They deliver stable performance in compact devices where space is limited. With high reliability and cost efficiency, they power millions of consumer products worldwide.

CEM-1 or FR-4, 1.6 mm, 1 oz, lead-free HASL — for remote controls, small appliances, and general modules.

Industrial Control Systems

Essential in automation and monitoring systems across industries. Our PCBs withstand high temperatures, vibrations, and continuous operation. This ensures consistent performance for long-term industrial reliability.

FR-4, 1.6 mm, 1–2 oz, OSP; conservative creepage/clearance for higher ambient temperatures.

Medical Devices

Reliable and precise PCBs for life-saving equipment. They meet strict safety and performance standards for sensitive medical use. Our solutions help ensure accurate diagnostics and stable device operation.

FR-4, 0.8–1.6 mm, 1 oz; clean silkscreen reference designators and test pads for serviceability.

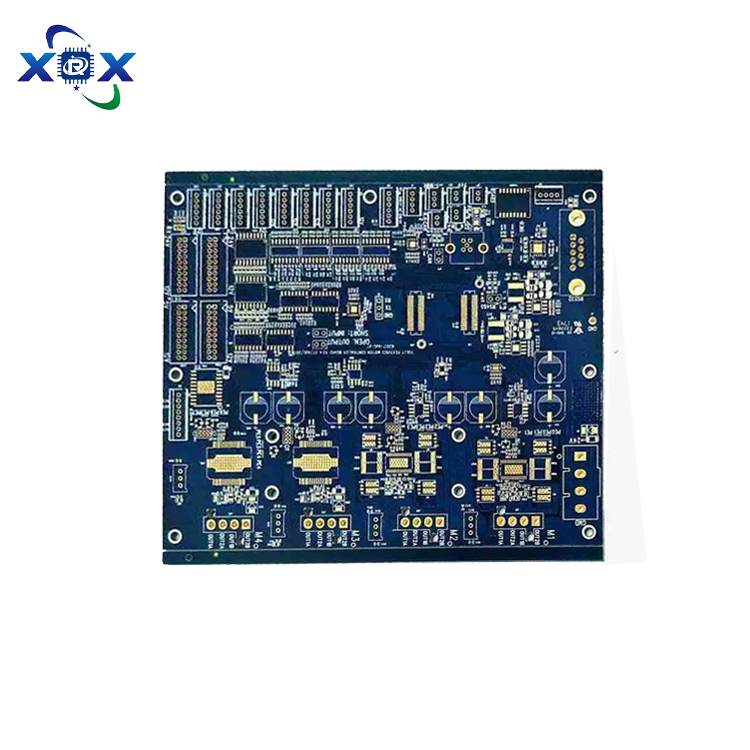

Single-Sided vs. Double-Sided PCBs

Choosing between single-sided and double-sided PCBs depends on cost, circuit complexity, and performance requirements. Both have advantages, but they serve different design and production scenarios. Understanding the trade-offs helps you select the most efficient solution for your project.

When to Choose Single-Sided PCBs?

Cost priority: Single-sided boards are the most economical option, ideal for high-volume and price-sensitive applications.

Simple routing: Best for circuits with straightforward layouts where all traces fit on one side.

Low-to-moderate performance needs: Suitable for analog, low-frequency, or less complex digital designs.

Typical applications: Household electronics, power supplies, LED modules, consumer gadgets, and entry-level appliances.

Manufacturing advantage: Faster production cycle and lower defect risk since only one copper layer is processed.

When to Choose Double-Sided PCBs?

Higher circuit density: Two copper layers provide more routing space, enabling compact designs.

Improved electrical performance: Ground planes and power distribution layers reduce EMI and support higher-speed signals.

More components, less size: Allows for more components in a smaller footprint, supporting miniaturization.

Typical applications: Industrial controllers, automotive electronics, medical devices, communication products.

Flexibility in design: Designers can cross traces on different layers, making complex circuits practical without large board sizes.

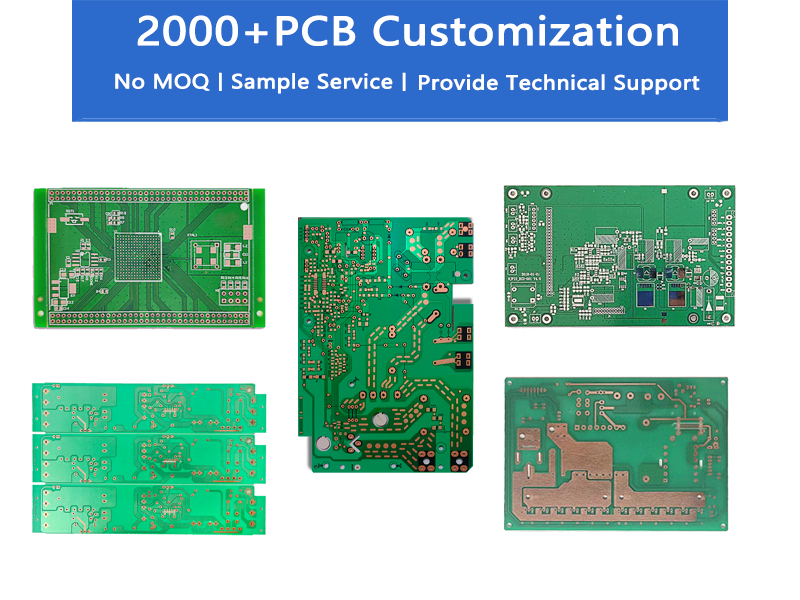

Why choose us

We ensure product stability and meet international standards with advanced production and strict quality control.

Highly Reliable and High Precision

We cater to diverse needs by offering a wide range of specifications and tailored services.

Diverse Specifications and Customized Services

Timely delivery and comprehensive after-sales support guarantee customer satisfaction.

Comprehensive Logistics Delivery System

Related Product

Custom 9x15 8x12 7x9 6x8 5x7 4x6 3x7 2x8 cm Universal circuit board Custom PCB Manufacturer

CEM-1 single-sided printed circuit board factory custom high quality circuit board applied to consumer electronics

Factory Customized Single-sided Printed Circuit Board FR-4 Material Electroplating Process

Customized Electronics FR-4 Single-Sided PCB Spacing Electronic Circuit Board Manufacturer

Customized Production of Single-sided Printed Circuit Boards for Application in Household Appliances And Consumer Electronics

FAQs

Related Blogs

-

Have you ever wondered what makes aerospace systems reliable in extreme environments? In the aerospace industry, every component must perform flawlessly under intense conditions. PCBs (Printed Circuit Boards) are the backbone of these systems, ensuring everything from navigation to communication works smoothly.Blogs

Have you ever wondered what makes aerospace systems reliable in extreme environments? In the aerospace industry, every component must perform flawlessly under intense conditions. PCBs (Printed Circuit Boards) are the backbone of these systems, ensuring everything from navigation to communication works smoothly.Blogs

Keep in Touch With Us

For more details on our Single Sided PCBs or to discuss your specific requirements, reach out to our customer service team.

Tel: +86-13724222511

E-mail: m18029051908@163.com