close

Choose Your Site

Global

Social Media

Views: 0 Author: Site Editor Publish Time: 2026-01-15 Origin: Site

Have you ever wondered which PCB material is best for your project? FR4 and Aluminum PCBs are both popular, but each offers unique advantages. In this article, we will discuss the key differences, performance factors, and applications of both materials. By the end, you'll have a clearer idea of which type suits your needs.

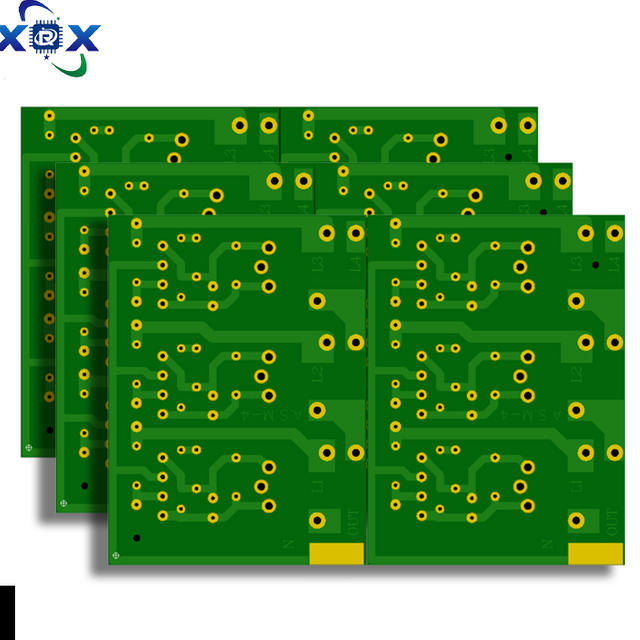

FR4 (Flame Retardant 4) is the most widely used material for creating PCBs. It is a composite made from woven fiberglass and epoxy resin, providing an excellent balance of electrical insulation, mechanical strength, and fire resistance. FR4 PCBs are primarily used in standard electronic devices due to their durability, affordability, and versatility. Its widespread use can be attributed to its balanced properties that make it an ideal choice for various applications, from consumer electronics to industrial systems.

● Material Composition: A combination of fiberglass and epoxy resin.

● Electrical Insulation: High dielectric strength ensures stable signal transmission.

● Fire Resistance: It meets fire safety standards, making it safe for a wide range of applications.

● Cost-Effectiveness: Inexpensive and widely available, making it ideal for mass production.

Key Advantages of FR4 PCB:

● Affordable for mass production

● Stable performance in moderate temperature ranges

● Easy to work with and readily available

Table: Key Features of FR4 PCB

Feature | Description |

Material | Fiberglass and epoxy resin |

Electrical Insulation | High dielectric strength |

Fire Resistance | Flame retardant according to UL standards |

Cost | Low, making it budget-friendly |

FR4 PCBs are used across various industries, including:

● Consumer Electronics: Smartphones, tablets, home appliances, laptops.

● Automotive Industry: Vehicle control systems, sensors, and infotainment systems.

● Telecommunications: Routers, network equipment, and signal transmission devices.

● Medical Devices: Diagnostic equipment and portable health gadgets.

FR4 is typically chosen for general-purpose applications where moderate temperature resistance and affordability are important.

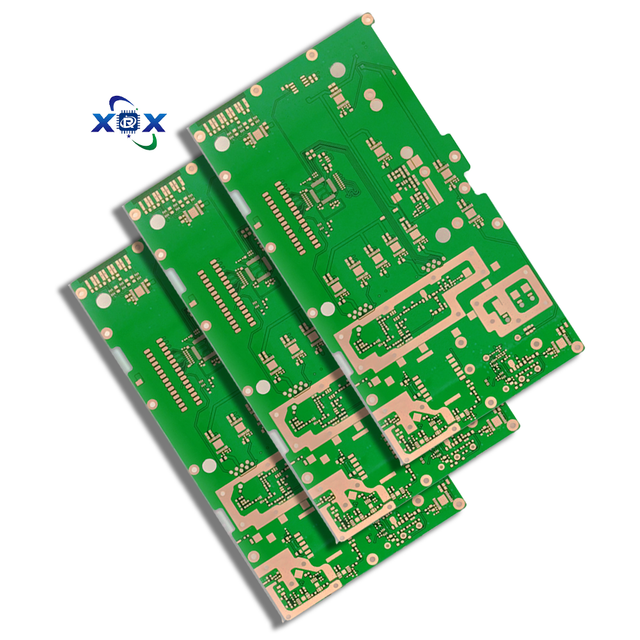

Aluminum PCBs are primarily used for applications that require efficient heat dissipation. The base material of these PCBs is an aluminum alloy, which provides superior thermal conductivity. This makes Aluminum PCBs ideal for high-performance applications where heat management is critical, such as power electronics, LED lighting, and high-power motor controls. Aluminum PCBs often feature a dielectric layer between the copper trace and the aluminum base, ensuring electrical insulation.

● Superior Heat Dissipation: The aluminum base allows for efficient heat transfer, preventing components from overheating and improving performance.

● Durability: Aluminum provides mechanical strength and resistance to external stresses, such as vibration and extreme environmental conditions.

● Electrical Insulation: Similar to FR4, Aluminum PCBs feature an insulating layer to prevent electrical leakage.

● Compact Design: The use of aluminum reduces the weight and size of the PCB, making it suitable for compact devices without sacrificing performance.

Table: Key Features of Aluminum PCB

Feature | Description |

Material | Aluminum alloy base |

Heat Dissipation | Excellent heat management |

Mechanical Strength | High durability and resistance |

Electrical Insulation | Insulating layer for safety |

Aluminum PCBs are widely used in applications where heat management is essential:

● LED Lighting: Ensures LEDs operate efficiently by dissipating heat and enhancing their lifespan.

● Power Supply Units: Helps maintain safe temperatures in power electronics, such as transformers and inverters.

● Automotive Industry: Used in electric vehicle circuits, sensors, and systems that generate significant heat during operation.

● Aerospace: Provides efficient cooling and electrical insulation in aerospace systems and high-tech equipment.

● FR4 PCB: Made from woven fiberglass and epoxy resin.

● Aluminum PCB: Made from aluminum alloy, often with a dielectric layer and copper traces.

Feature | FR4 PCB | Aluminum PCB |

Base Material | Fiberglass and epoxy resin | Aluminum alloy |

Heat Dissipation | Standard (not highly conductive) | Superior heat dissipation |

Electrical Insulation | Excellent | Requires additional insulation |

Heat dissipation is a key factor in high-performance applications. Aluminum PCBs have a significant advantage when it comes to thermal performance. Aluminum’s high thermal conductivity allows for more efficient heat transfer, which is critical in applications such as LED lighting and power supply units where heat management is essential to prevent overheating.

In contrast, FR4 PCBs are less effective at heat dissipation. While they can handle moderate heat levels, they are better suited for applications that do not generate significant amounts of heat.

Aluminum PCBs are more durable, especially in environments that experience high temperatures, mechanical stress, and vibration. For example, automotive and industrial systems that experience frequent shocks and vibrations benefit from Aluminum PCBs due to their mechanical strength and ability to withstand harsh conditions. FR4 PCBs, while still reliable, are more susceptible to damage from physical stress and high temperatures, making them less suitable for extreme environments.

● FR4 PCBs are cheaper to manufacture, making them an excellent choice for mass production in low to medium power applications.

● Aluminum PCBs, on the other hand, are more expensive due to the complexity of their manufacturing process and the additional steps required for heat management and mechanical strength.

Tip: When budget constraints are a factor, FR4 PCBs are typically the better choice for general applications, while Aluminum PCBs should be considered for high-performance, heat-sensitive devices.

● FR4 PCB: Ideal for low to moderate power circuits, providing excellent electrical insulation and stability. The fiberglass and epoxy resin construction offer high resistance to electrical leakage.

● Aluminum PCB: Provides stable electrical performance even at higher temperatures, due to superior heat dissipation. This is important in power electronics where excessive heat can lead to malfunction.

● FR4 PCB: Moderate heat resistance, making it suitable for less thermally demanding applications.

● Aluminum PCB: Superior thermal conductivity, crucial for applications that generate significant heat, such as LED circuits, power electronics, and automotive sensors.

Feature | FR4 PCB | Aluminum PCB |

Electrical Performance | Stable at low-medium power | High power tolerance |

Heat Dissipation | Moderate | Superior |

Mechanical Strength | Standard | High |

Aluminum PCBs are far superior in mechanical performance, offering higher durability and strength, which is essential for demanding industrial environments. They are resistant to vibrations, shocks, and extreme temperatures, making them ideal for applications such as electric vehicles and industrial sensors. FR4 PCBs are more fragile, making them less suitable for these high-stress applications.

FR4 PCBs are best suited for applications where:

● Cost-Effectiveness is a priority.

● Standard Electronics are being used with moderate heat and power requirements.

Examples of ideal uses include consumer electronics, telecommunications, and low-power circuits where heat generation is minimal.

Aluminum PCBs should be chosen when:

● Heat Dissipation is critical.

● The application involves high-power circuits, such as LED lighting or power electronics.

Examples of ideal uses include high-performance systems, automotive electronics, LED lighting solutions, and other heat-sensitive applications.

While FR4 PCBs are more budget-friendly, Aluminum PCBs offer superior performance in thermal management, which justifies their higher cost in certain applications. When making the decision, it's crucial to weigh the performance needs of your project against the available budget.

Tip: Choose FR4 PCBs for standard, budget-sensitive projects, and Aluminum PCBs for high-performance applications that demand efficient heat dissipation.

With the increasing demand for more powerful and compact electronics, both FR4 and Aluminum PCBs are undergoing significant improvements. FR4 materials are evolving with higher temperature ratings and better performance in high-frequency applications. Meanwhile, Aluminum PCBs are incorporating more advanced thermal management features, with the potential to integrate new materials that offer even better heat dissipation.

As electronics become more complex, industries such as automotive, healthcare, and consumer electronics are pushing the need for specialized PCBs. This trend is driving the development of hybrid PCBs that combine the strengths of both FR4 and Aluminum PCBs for tailored solutions in sectors like electric vehicles and medical devices.

This article highlighted the essential differences between FR4 and Aluminum PCBs. We explored their material compositions, performance capabilities, and industry applications. For those in need of high-performance, heat-dissipating PCBs, Dongguan Xinrongxing Technology Co., Ltd. offers quality Aluminum PCBs, providing excellent thermal management and durability for demanding industries.

A: FR4 PCB is a type of printed circuit board made from fiberglass and epoxy resin. It is widely used in standard electronic devices due to its electrical insulation, durability, and fire resistance.

A: Unlike FR4 PCB, Aluminum PCB uses an aluminum alloy as its base material, providing superior heat dissipation. This makes Aluminum PCBs ideal for high-power applications like LED lighting.

A: FR4 PCBs are cost-effective, widely available, and offer sufficient performance for standard applications. They are ideal for low to medium-power devices where heat management is not critical.

A: Aluminum PCBs are used in applications requiring efficient heat management, such as LED lights, power supply units, and automotive systems.

A: Yes, Aluminum PCBs are more expensive due to their advanced manufacturing process and superior heat dissipation capabilities, making them suitable for high-performance, heat-sensitive applications.