close

Choose Your Site

Global

Social Media

Views: 0 Author: Site Editor Publish Time: 2025-11-07 Origin: Site

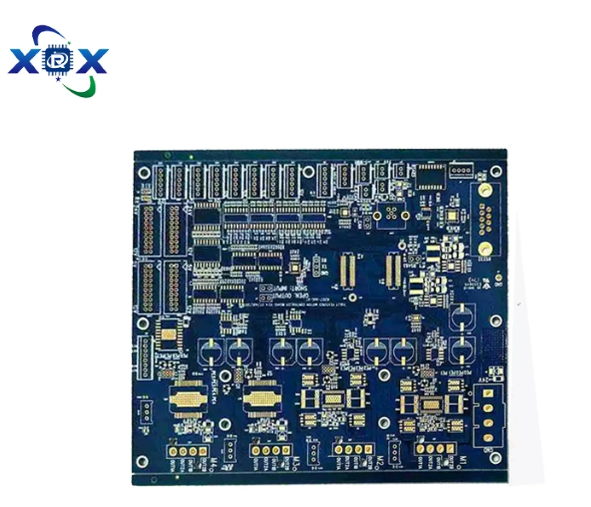

PCB manufacturing is key to modern electronics. It shapes devices from phones to industrial systems. Producing high-quality PCBs requires precise materials, accurate layers, and careful fabrication. In this article, you will learn a PCB manufacturing process guide. We explain step-by-step fabrication, testing, and assembly. Readers will discover how to optimize performance, reduce errors, and improve production efficiency.

Design specifications define the foundation for successful PCB manufacturing. Layer count, board thickness, trace width, and spacing all impact signal integrity and thermal performance. Higher layer counts improve routing density but increase complexity. Designers must consider how these parameters interact with materials and assembly techniques to ensure functionality and reliability across operating conditions. Controlled impedance, proper spacing, and careful trace routing are critical for high-speed and high-frequency PCBs.

Selecting the right material is crucial. Standard FR-4 suits low- to mid-frequency applications, while high-frequency laminates like Rogers or PTFE are essential for mmWave designs. Material choice affects dielectric constant, dissipation factor, thermal stability, and cost. High-frequency PCB layout for 5G requires materials that maintain consistent impedance and minimize signal loss. Designers must weigh cost against electrical and mechanical performance, especially in multilayer PCB manufacturing best practices.

Gerber files are the industry standard for PCB fabrication instructions. They include copper layers, drill patterns, solder mask, and silkscreen data. Accurate output ensures manufacturers correctly interpret the design and avoid costly errors. File validation before submission reduces back-and-forth and expedites production. Designers should also provide detailed drill drawings, stack-up notes, and assembly instructions to support seamless PCB production and assembly workflow.

DFM principles enhance yield and reliability. Avoid overly thin traces, tight spacing, or complex geometries that exceed fabrication tolerances. Ensuring components are accessible for assembly and testing is essential. Designers should simulate thermal and signal behavior to anticipate issues before fabrication. Following PCB manufacturing process guide recommendations on DFM reduces scrap and improves first-pass success rates.

Lamination binds copper-clad layers with resin and pre-preg sheets under heat and pressure. This process forms a solid substrate capable of supporting multilayer designs. Uniform pressure and temperature are critical for preventing voids, warping, or delamination. Lamination quality directly affects signal integrity and mechanical strength, especially in high-layer-count boards.

Layer arrangement influences impedance, crosstalk, and heat dissipation. Ground and power planes are strategically placed to reduce EMI and maintain consistent electrical performance. Designers follow multilayer PCB manufacturing best practices to optimize stack-ups for high-frequency signals. Symmetrical stacking prevents warping and simplifies thermal management in dense boards.

PCB surface finishes improve solderability, protect copper traces, and ensure long-term durability. Common finishes include HASL, ENIG, and OSP. Each offers trade-offs in cost, flatness, and suitability for automated assembly. The choice of finish impacts the reliability of solder joints and the lifespan of high-speed components.

Layer | Material | Function | Notes |

Core 1 | FR-4 | Signal routing | Standard layers for sub-6 GHz |

Core 2 | High-Freq Laminate | RF traces | Low Dk/Df for mmWave signals |

Pre-Preg | Epoxy | Insulation | Controls dielectric thickness |

Copper Foil | Cu | Conductive layers | Thickness depends on current load |

Photoresist coatings protect selected copper areas from etching, forming the precise circuit patterns required for functional PCBs. Uniform application ensures trace widths are consistent across layers, which is critical for signal integrity and high-frequency performance. Both liquid and dry-film resists are widely used, with selection based on layer count, line resolution, and production scale. Careful handling prevents defects such as pinholes or uneven coverage, which could compromise subsequent etching and overall board reliability.

During UV exposure, the PCB design is transferred from a photomask onto the photoresist layer, defining the conductive paths. Precise alignment is especially critical for multilayer boards to ensure interlayer connectivity. Exposure time and intensity must be rigorously controlled to prevent overexposure, which can reduce trace width, or underexposure, which leaves residual resist and causes etching errors. Proper masking and alignment reduce errors, enabling accurate replication of complex high-density interconnect (HDI) designs.

Chemical etching removes unprotected copper to form the desired circuit layout. The process requires carefully selected etchants, temperature control, and timing adjustments to maintain uniformity and avoid undercutting or incomplete removal. Trace width, spacing, and aspect ratios are considered to maintain electrical performance, particularly in multilayer PCBs where crosstalk and impedance control are critical. Consistent etching ensures reliable current flow and prevents shorts or opens, which are costly to repair after assembly.

After etching, the residual photoresist is removed and boards are thoroughly cleaned. This step eliminates contaminants that could interfere with plating, soldering, or adhesive bonding for additional layers. Proper cleaning improves adhesion of surface finishes and prevents oxidation or corrosion, which is essential for long-term reliability. Thorough rinsing and drying are critical in maintaining dimensional stability and avoiding defects in subsequent assembly

Mechanical drilling creates through-hole, blind, and buried vias that interconnect PCB layers. Drill size, feed rate, and rotation speed must be calibrated to the substrate material and copper thickness to prevent delamination or burr formation. Accurate drilling ensures proper electrical continuity and supports component placement and soldering reliability. For multilayer boards, precise positioning of vias is essential to maintain impedance control and avoid short circuits in high-frequency applications.

High-density interconnect PCBs require laser drilling for microvias smaller than 150 µm. This method reduces mechanical stress on the board and allows compact designs without compromising electrical performance. Laser drilling supports stacked or staggered via structures essential for modern multilayer boards used in mobile, IoT, or high-speed computing applications. Precision in laser drilling directly affects via quality, layer alignment, and signal integrity.

Plating vias with copper ensures electrical continuity across layers and enhances mechanical stability. Uniform deposition prevents resistance variation, which is critical for signal integrity in high-frequency PCBs. Post-plating inspections verify via connectivity and detect voids or incomplete plating. Proper plating techniques also improve thermal dissipation paths and prepare the board for subsequent soldering, surface finish, and assembly steps.

Drilled and plated boards undergo optical and electrical inspections to confirm hole placement, size, and continuity. Detection of misalignment, incomplete plating, or debris is critical for preventing assembly failures. Automated inspection systems and manual checks ensure that boards meet precise specifications, particularly for HDI and multilayer PCBs. Maintaining strict quality standards reduces rework, scrap, and production delays.

Solder masks protect copper traces from oxidation and prevent solder bridging during component assembly. Uniform application thickness is critical for automated pick-and-place processes. Inconsistent coating can cause shorts or poor solder adhesion. Advanced techniques ensure even coverage, particularly for fine-pitch components and high-density boards.

Silkscreen printing marks component identifiers, logos, and reference designators on the PCB. Accurate and legible silkscreen is essential for assembly and troubleshooting. Misalignment or smudging can create confusion during automated or manual assembly processes, leading to errors or delays. Proper curing and ink selection improve durability and chemical resistance.

After application, solder masks and silkscreens are cured using UV or thermal methods. Proper curing ensures the coatings are mechanically robust, chemically resistant, and dimensionally stable. Insufficient curing can lead to peeling, contamination, or reduced adhesion, affecting assembly quality and long-term reliability.

Visual inspection and automated optical inspection (AOI) verify the integrity of solder masks and silkscreens. Defects like voids, misprints, or smudges are identified and corrected before assembly. Consistent inspection ensures high assembly yields, reduces rework, and improves final product reliability.

Surface finishes such as HASL, ENIG, and OSP provide crucial protection for copper traces while enhancing solderability for both automated and manual assembly. Selecting the right finish depends on the soldering method, component type, expected thermal cycling, and long-term reliability requirements. Additionally, proper finishes help minimize oxidation, support consistent high-frequency signal integrity, and prevent delamination in multilayer or HDI boards. Choosing appropriate surface treatment ensures mechanical robustness and prepares the PCB for subsequent assembly, reflow soldering, and harsh operating environments.

Maintaining flatness and planarity is essential for automated pick-and-place assembly and soldering precision. Warped or uneven boards can result in misaligned components, solder bridging, or thermal stress, which negatively impacts yield and functional reliability. Planarity verification ensures consistent contact between pads and components, particularly for HDI and multilayer boards with fine-pitch components. This step improves process repeatability in mass production, reduces rework, and supports long-term durability of the assembled PCB in demanding industrial or consumer applications.

Comprehensive electrical testing ensures boards are free of shorts, opens, and impedance deviations before entering assembly. Early detection of defects prevents costly rework or functional failures in downstream processes. Testing validates the PCB against design specifications, including trace continuity, signal integrity, and power handling. Functional verification is especially critical for multilayer and high-frequency boards where minor faults can compromise overall system performance. By integrating systematic testing, manufacturers guarantee reliability, reduce field failures, and ensure high-quality PCB production.

Proper packaging protects PCBs during storage and shipment to assembly plants. Anti-static bags, cushioning materials, and rigid containers prevent mechanical damage, electrostatic discharge, or warping. Correct handling minimizes contamination and ensures boards maintain planarity and surface finish integrity. For multilayer and HDI boards, packaging consistency is vital to avoid bending or scratches that could interfere with soldering or signal performance. Secure packaging also facilitates streamlined logistics, reduces the risk of defects, and supports high-volume manufacturing efficiency.

Electrical testing, including flying probe and bed-of-nails methods, validates connectivity and functionality across all PCB layers. This step ensures each circuit path operates correctly, particularly in multilayer or HDI designs where access to internal traces is limited. Testing helps detect opens, shorts, or high-resistance connections, reducing the risk of failure during assembly or final operation. Accurate electrical verification improves yield, lowers scrap rates, and confirms that each PCB meets design and industry standards for performance and reliability.

PCB reliability is enhanced by thermal and environmental stress testing, which simulates real-world operating conditions such as temperature fluctuations, humidity, vibration, and mechanical shock. These tests verify that boards can withstand harsh conditions without warping, delamination, or electrical failure. Stress testing is particularly important for multilayer, HDI, or high-speed PCBs where thermal expansion and contraction may affect impedance or signal integrity. Conducting these evaluations ensures long-term durability, reliability, and consistent performance under diverse operational scenarios.

Automated Optical Inspection (AOI) and visual checks identify micro-defects such as misaligned traces, incomplete solder masks, or surface contamination. AOI ensures that each board complies with design specifications before assembly, reducing the likelihood of defective products reaching production lines. Combining automated inspections with manual verification enables detection of subtle defects, maintaining high standards of quality for complex multilayer and HDI boards. This process improves overall yield, minimizes rework, and ensures consistency in high-volume PCB manufacturing.

Compliance with ISO and IPC standards guarantees PCBs meet international quality, reliability, and reproducibility benchmarks. Following these guidelines ensures boards perform reliably in commercial, automotive, and high-speed electronics applications. Adherence to standards supports traceability, reduces liability risks, and enhances customer confidence. ISO and IPC certification also demonstrates process control, effective quality management, and commitment to manufacturing excellence, which is essential for high-performance and high-reliability PCBs.

Material inconsistencies, including variations in laminates or copper properties, can impact impedance, thermal performance, and layer adhesion. Uniform material quality is critical for high-speed, multilayer, or HDI boards where small deviations can degrade signal integrity or mechanical reliability. Manufacturers must monitor material properties, select consistent suppliers, and test incoming stock to ensure predictable performance. Effective material control reduces defects, supports repeatable manufacturing processes, and prevents costly revisions during assembly or in-field use.

HDI PCBs with fine traces, microvias, and dense routing present unique manufacturing challenges. Precision drilling, plating, and alignment are required to maintain electrical continuity and prevent functional failure. Even minor deviations can cause impedance mismatches, short circuits, or signal degradation, particularly in high-speed or RF applications. Careful process control, advanced equipment, and rigorous inspection are essential to reliably produce HDI designs while maintaining yield and performance standards.

Balancing material quality, process complexity, and production schedules directly affects cost and lead time. Strategic planning is required to optimize resources, reduce waste, and meet project deadlines. For multilayer or HDI PCBs, extended processing times and advanced fabrication techniques can increase costs. Manufacturers must weigh design requirements against budget constraints, prioritize critical process steps, and maintain transparent communication with stakeholders to ensure on-time delivery without compromising board performance.

Prototyping, iterative testing, and close collaboration with fabricators significantly reduce manufacturing errors. Early identification of design flaws, material inconsistencies, or process deviations improves yields and minimizes scrap. Implementing robust error prevention strategies ensures consistent production of high-performance PCBs, even for complex multilayer or high-density designs. Proactive planning, verification, and quality monitoring allow manufacturers to maintain reliability, reduce rework, and meet stringent industry standards efficiently.

PCB manufacturing requires careful design, precise materials, and controlled assembly. Following a PCB manufacturing process guide ensures reliable, high-performance boards. Implementing multilayer PCB manufacturing best practices improves quality and yield. Understanding the step-by-step PCB fabrication process and PCB production and assembly workflow enables efficient production. Dongguan Xinrongxing Technology Co., Ltd. provides advanced PCB solutions that enhance reliability and performance, helping engineers achieve optimized, error-free outcomes.

A: The PCB manufacturing process involves designing, patterning, drilling, plating, applying solder masks, and testing boards. Following a PCB manufacturing process guide ensures high-quality, reliable circuit boards.

A: Preparing a PCB design includes defining specifications, selecting materials, generating Gerber files, and applying DFM principles. Using a step-by-step PCB fabrication process reduces errors and improves yields.

A: Material affects thermal performance, impedance, and reliability. Choosing the right laminate or copper ensures proper operation and long-term durability. Multilayer PCB manufacturing best practices guide these choices.

A: Stack-up design influences signal integrity, EMI, and thermal management. Optimized multilayer layouts following multilayer PCB manufacturing best practices prevent warping and support high-frequency performance.

A: Challenges include material variability, high-density interconnects, and cost management. Using a PCB production and assembly workflow with proper testing reduces errors and improves reliability.

A: Quality is verified through electrical tests, thermal stress simulations, AOI inspections, and adherence to ISO and IPC standards. Following a PCB manufacturing process guide enhances consistency.

A: Early prototyping, iterative testing, and close collaboration with fabricators minimize mistakes. A step-by-step PCB fabrication process helps detect design issues before mass production.

A: Solder masks prevent bridging and protect copper, while silkscreens label components. Applying these coatings correctly improves assembly accuracy and yield.

A: HDI PCBs use precision laser drilling for small vias, reducing mechanical stress and improving connectivity. This supports compact and high-performance board designs.

A: Electrical, thermal, and visual inspections ensure shorts, opens, and impedance issues are detected. This final step confirms functionality and supports high-quality production.