close

Choose Your Site

Global

Social Media

Views: 0 Author: Site Editor Publish Time: 2025-11-07 Origin: Site

Ever wondered what makes electronics work? PCB components control signals and power, forming the backbone of every device. In this article, we explore their key roles, functions, types, and applications. You will learn how mastering these parts improves PCB design, reliability, and overall system performance.

Resistors are fundamental components that control current flow. They limit excessive current to protect sensitive parts and divide voltage in circuits. Resistors come in axial, surface-mount, and precision types, each offering different tolerances and power ratings. Selecting the right resistance ensures circuit stability and prevents overheating. They are widely used in voltage dividers, biasing transistors, and terminating transmission lines.

Table 1: Common Resistor Types

Type | Application | Power Rating | Tolerance |

Axial Resistor | General purpose | 0.25W–2W | ±1% to ±5% |

Surface-Mount | Compact PCBs | 0.125W–1W | ±0.5% to ±5% |

Precision | Sensitive analog circuits | 0.25W–0.5W | ±0.1% |

Capacitors store energy temporarily and smooth voltage fluctuations. They are essential for AC/DC filtering, voltage stabilization, and timing circuits. Ceramic, electrolytic, and polymer capacitors offer varied characteristics such as stability, capacitance range, and ESR. Placement and orientation affect high-frequency performance and minimize interference. Capacitors also help in tuning circuits and improving power supply quality.

Inductors store energy in magnetic fields and oppose AC signals. They are commonly used in power regulation, filtering, and radio-frequency circuits. Selection involves choosing proper inductance values to match desired circuit responses. Inductors often work with capacitors to form LC filters that reduce noise and stabilize power rails. The physical layout impacts inductance and coupling, which is critical for high-speed PCBs.

Potentiometers adjust voltage manually and are useful for calibration and tuning. They exist in rotary and linear forms and can control signal levels in audio, sensor, and measurement circuits. Variable resistors are integrated carefully to maintain reliability. Correct placement ensures accessibility while avoiding interference with other PCB components.

Diodes are essential for controlling the direction of current flow, preventing damage to sensitive components. They serve as rectifiers, voltage regulators, signal modulators, and protection devices. Common types include standard, Zener, Schottky, and LEDs, each suited for specific voltage, frequency, or power applications. Correct orientation on the PCB is critical, as reversing a diode can block current or cause component failure. Diodes are especially valuable in circuits requiring fast switching, voltage clamping, or reverse polarity protection.

Transistors act as amplifiers and switches, forming the backbone of modern electronics. Bipolar Junction Transistors (BJTs) handle linear amplification, while Field Effect Transistors (FETs) offer low-power, high-speed switching. Proper placement on a PCB affects thermal management and signal integrity, ensuring reliable operation. Transistors are used in analog amplification, digital logic, and signal modulation circuits. Thermal considerations, such as heat sinks or copper pours, are critical to avoid overheating and maintain long-term stability, especially in densely populated PCBs.

SCRs are high-power semiconductor devices designed for controlled AC switching. They conduct after receiving a gate trigger and continue until current drops below a threshold. SCRs are widely applied in motor drives, industrial power controllers, and AC regulation systems. Integration into PCBs requires careful layout to manage heat dissipation and protect surrounding components. Protective circuitry, such as snubber networks or fuses, ensures longevity and prevents accidental triggering or failure in high-voltage applications. Proper selection of SCR voltage and current ratings is essential for reliable operation.

ICs consolidate multiple transistors, diodes, and resistors into compact modules capable of complex functions. They are used in signal processing, computation, control systems, and memory modules. PCB designers must consider footprint, thermal dissipation, and routing to maintain signal integrity and prevent overheating. Surface-mount or through-hole ICs require precise soldering techniques to ensure reliable electrical contact. ICs simplify circuit design by reducing component count, saving board space, and enabling higher functionality in compact electronic systems.

Crystal oscillators provide precise clock signals for microcontrollers, processors, and digital communication circuits. Compared to ceramic resonators, they offer higher frequency stability and minimal drift over time. Placement on the PCB affects signal quality, and careful decoupling with capacitors ensures stable oscillation. Crystal oscillators are used in timekeeping, frequency generation, and synchronous digital circuits. Designers must account for temperature variations and interference to preserve timing accuracy. Proper footprint selection ensures mechanical stability and prevents vibration-induced frequency errors.

Oscillators generate accurate frequencies for microprocessors, RF circuits, and communication modules. Integration with passive components, such as capacitors and resistors, helps stabilize output signals and minimize jitter or crosstalk. Routing traces carefully reduces interference between oscillators and nearby signal lines. Frequency stability is essential in applications like wireless communication, audio processing, and clock distribution networks. Designers must verify oscillator specifications to ensure correct timing, synchronization, and compatibility across the entire system.

Switches allow manual control of electrical circuits and are available in push-button, toggle, rotary, and slider types. Choosing switches requires attention to current rating, mechanical durability, and user interface ergonomics. Proper layout ensures accessibility, minimizes accidental activation, and supports long-term reliability. Switches interface human input with electronic systems, controlling power delivery or selecting operational modes. Selecting high-quality switches extends PCB longevity, especially in frequently operated devices.

Relays use low-power signals to control high-power circuits, providing isolation and protection for sensitive components. Coil voltage, contact ratings, and switching speed determine their suitability for different applications. Placement on the PCB must consider heat dissipation, electromagnetic interference, and mechanical stress. Relays are critical in industrial automation, motor control, and safety circuits. Choosing relays with long operational lifespans ensures reliable performance in high-current environments.

Connectors provide secure electrical interfaces between the PCB and external devices. They include headers, sockets, and edge connectors, each designed for specific mechanical and electrical requirements. Proper selection ensures signal integrity, prevents accidental disconnection, and supports assembly efficiency. Mounting techniques, whether surface-mount or through-hole, affect mechanical stability and durability. Connectors are essential in modular systems, allowing maintenance, upgrades, and reliable power or signal transmission.

Transformers modify AC voltage levels and provide electrical isolation between circuits. They are crucial for power distribution, safety-critical designs, and energy conversion. PCB placement, orientation, and magnetic shielding reduce electromagnetic interference. Transformers generate heat, so thermal management strategies, including copper pours or heat sinks, are essential. Designers must select transformers that match voltage, current, and frequency requirements to ensure efficiency and reliable operation in industrial and consumer electronics.

Environmental sensors detect temperature, humidity, light, or motion, converting physical changes into electrical signals. Compact PCB integration requires careful orientation, trace routing, and shielding to prevent interference. Power management ensures consistent performance and accuracy. These sensors are critical in IoT, wearable electronics, and automated monitoring systems, providing reliable feedback for control and decision-making.

Specialized sensors, including pressure, gas, and proximity types, serve advanced industrial, automotive, and IoT applications. Signal conditioning circuits enhance accuracy and reduce noise. Proper PCB layout and placement prevent cross-talk, electromagnetic interference, and mechanical strain. Using high-quality components ensures reliable operation under varying environmental conditions.

Sensor performance is highly dependent on orientation, trace layout, and proximity to noise sources. Minimizing interference and providing stable power supply lines enhances reliability. Designers must consider thermal and electromagnetic factors when placing sensors to maintain precise and repeatable measurements across different operational conditions.

Passive components, such as resistors, capacitors, and inductors, respond linearly to current and voltage, while active devices, like transistors and ICs, behave non-linearly. Understanding this distinction allows designers to optimize performance, minimize distortion, and implement precise signal control. Circuits combining both passive and active elements balance energy efficiency and functional flexibility.

Passive elements dissipate energy as heat, whereas active components switch efficiently, minimizing power loss. Designing for thermal balance improves longevity and performance. Engineers must evaluate trade-offs between dissipation, switching speed, and system reliability. Efficient energy management reduces cooling requirements and enhances PCB compactness.

Selecting components involves matching voltage, current, frequency, and environmental requirements. Cost, performance, availability, and footprint influence final choices. Simulation and prototyping verify correct function and identify potential issues before production. Proper selection enhances system stability, reduces rework, and ensures product reliability.

Group related components to reduce trace lengths, minimize interference, and improve thermal management. Strategic spacing enhances airflow, prevents crosstalk, and simplifies assembly. Following layout best practices enables high-performance, scalable PCB designs. Proper planning ensures functional clarity and operational reliability across the entire board.

Through-hole and surface-mount technologies each offer distinct benefits. Correct soldering prevents cold joints, bridges, or mechanical failures. Inspection after assembly ensures continuity, mechanical stability, and electrical performance. Choosing the appropriate technique depends on component type, production volume, and mechanical constraints.

Testing verifies component operation, signal integrity, and connectivity. Multimeters, oscilloscopes, and automated testers detect early faults, allowing prompt correction. Documentation of test results creates a reference for future troubleshooting. Effective testing improves production efficiency, reduces rework, and enhances long-term reliability of PCB assemblies.

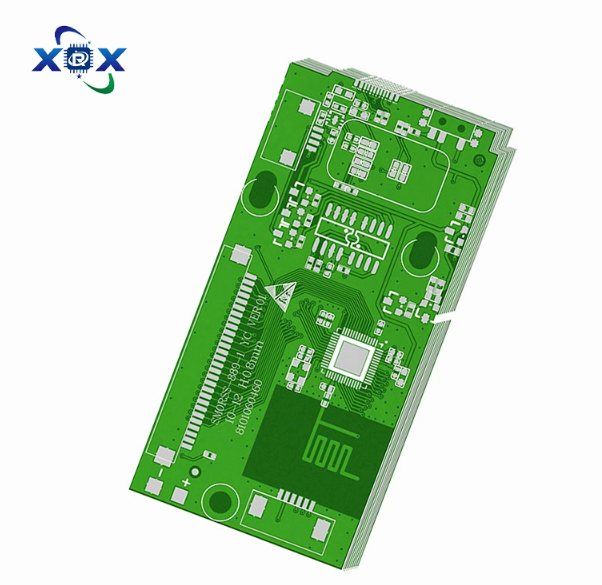

Understanding PCB components is essential for reliable designs. Passive and active parts shape circuit performance. Electromechanical components and sensors enhance functionality. Dongguan Xinrongxing Technology Co., Ltd. offers high-quality PCBs that improve efficiency and reduce errors, delivering reliable solutions for diverse electronic applications.

A: Common PCB components include resistors, capacitors, inductors, diodes, transistors, ICs, switches, relays, and connectors. Understanding typical PCB components explained helps ensure efficient circuit design.

A: Diodes control current direction on PCB, protecting circuits and rectifying voltage. Following a PCB component functions guide ensures correct orientation and reliable operation.

A: Transistors amplify signals and act as switches. Knowing electronic components on PCB and their placement ensures optimal performance and reduced thermal issues.

A: Capacitors store energy, stabilize voltage, and filter noise. Common PCB parts and functions highlight their importance in maintaining circuit stability and signal integrity.

A: Sensors detect environmental changes and convert them to signals. Following a PCB component functions guide ensures accurate readings and minimal interference.

A: Passive components like resistors and capacitors dissipate energy, while active components such as transistors and ICs control signals. Understanding typical PCB components explained aids design efficiency.

A: Select connectors based on signal type, current rating, and mechanical stability. Using a PCB component functions guide ensures proper integration and reliable connectivity.

A: Yes, improper layout can cause overheating, interference, or signal loss. Following common PCB parts and functions ensures optimal routing and long-term reliability.

A: Crystal oscillators provide precise timing for microcontrollers and communication circuits. Knowing electronic components on PCB ensures synchronization across modules.

A: Use multimeters and oscilloscopes to test common PCB parts and functions. Following a PCB component functions guide helps identify failures efficiently.