close

Choose Your Site

Global

Social Media

Views: 0 Author: Site Editor Publish Time: 2026-01-15 Origin: Site

Have you ever wondered how modern electronics achieve the perfect balance between cost and performance? High-volume PCB manufacturing is the answer. In this article, we will explore the numerous benefits and key applications of high-volume PCB manufacturing. You will learn how this process enables industries to create efficient, reliable, and cost-effective products at scale.

High-volume PCB manufacturing offers several key advantages that not only enhance production efficiency but also provide businesses with a competitive edge. Below are some of the primary benefits:

One of the most significant benefits of high-volume PCB manufacturing is its ability to reduce the cost per unit. As demand for PCBs increases, manufacturing them in large quantities allows businesses to benefit from economies of scale, making production more cost-effective.

● Lower Unit Cost: Producing PCBs in large batches allows manufacturers to amortize the initial setup costs over a greater number of units, reducing the cost per unit significantly.

● Material Savings: Bulk purchasing of materials results in substantial savings, as manufacturers can secure discounts from suppliers and reduce the overall cost of raw materials.

● Tooling Cost Reduction: Setting up the necessary tools and machinery for PCB manufacturing can be expensive. However, high-volume production allows these costs to be spread across a large number of units, which makes each unit's tooling cost lower.

Benefit | Effect |

Economies of scale | Lowers per-unit production costs |

Bulk material purchase | Decreases cost of raw materials |

Tooling cost savings | Reduces setup costs for high-volume production |

In high-volume PCB manufacturing, ensuring consistent quality is paramount. With a large number of units being produced, businesses must maintain strict quality standards to meet industry requirements and customer expectations.

● Automated Processes: Automation is key to ensuring the repeatability of every step in the production process. From etching to soldering, automation ensures precision and consistency across every batch of PCBs.

● Strict Quality Standards: High-volume production requires manufacturers to comply with international certifications and standards such as RoHS (Restriction of Hazardous Substances) and UL (Underwriters Laboratories), ensuring that every PCB meets safety and environmental guidelines.

● Continuous Monitoring: Real-time quality checks are conducted throughout the production process to minimize defects and ensure that only flawless PCBs reach the customer.

Investing in automated testing systems will help you streamline quality control processes, identifying issues early in the production cycle and ensuring reliable, defect-free products.

In today’s fast-paced markets, the speed at which products are developed and delivered can make or break a business. High-volume PCB manufacturing accelerates the production process, allowing companies to reduce lead times and deliver products quickly.

● Quick Turnaround: With the right technology and processes in place, high-volume manufacturing can significantly reduce production timelines, ensuring that products are delivered on schedule.

● Streamlined Manufacturing Process: Advanced machinery and optimized workflows ensure that each step in the production process is carried out efficiently, further reducing manufacturing time.

● Reliable Supply Chain: The predictability of high-volume production makes it easier to manage the supply chain, ensuring consistent delivery even during peak production periods.

Advantage | Impact |

Fast manufacturing cycle | Shorter lead time for product delivery |

Efficient processes | Ensures on-time production |

Predictable supply chain | Reduces delays and improves reliability |

Tip: By optimizing your production line for speed, you can increase throughput and reduce manufacturing costs. Lean manufacturing principles can help in reducing waste and improving efficiency.

High-volume PCBs are essential to numerous industries, where they are used to power a wide array of electronic devices. Below are some of the primary sectors that rely on high-volume PCB manufacturing.

The consumer electronics industry is one of the largest consumers of PCBs. From smartphones to televisions, the demand for high-quality, reliable PCBs is massive. High-volume PCB manufacturing plays a critical role in meeting this demand.

● Smartphones and Tablets: PCBs provide the power management, connectivity, and functionality needed for modern smartphones and tablets. High-volume production ensures that manufacturers can meet the global demand for these devices.

● Wearables: Devices like smartwatches and fitness trackers require compact, high-performance PCBs that support advanced features such as heart rate monitoring, GPS, and wireless connectivity.

● Home Appliances: Products like refrigerators, washing machines, and microwaves rely on PCBs for power distribution and control. High-volume PCB manufacturing ensures that these appliances meet consumer demand without compromising on quality.

Product | PCB Role |

Smartphones | Power management and connectivity |

Wearables | Miniaturized, high-performance PCBs |

Home appliances | Controls for operations and displays |

The automotive sector is increasingly dependent on advanced electronics for a range of applications, and high-volume PCB manufacturing supports this trend by delivering the necessary components.

● In-car Electronics: Modern vehicles rely on PCBs for a range of systems, including infotainment, navigation, climate control, and communication. High-volume PCB production ensures these systems function reliably.

● Electric Vehicles (EVs): High-performance PCBs are vital for managing battery power and controlling electric motor systems in EVs. As the demand for electric vehicles grows, the need for high-volume PCB manufacturing also increases.

● Safety Features: Advanced driver-assistance systems (ADAS) such as airbags, collision detection, and anti-lock braking systems (ABS) depend on PCBs for their functionality and reliability.

Automotive Application | PCB Function |

In-car systems | Power management and connectivity |

Electric vehicles | Battery management and control |

Safety systems | Performance and reliability |

The medical industry is highly reliant on PCBs for the functioning of various diagnostic and therapeutic devices. High-volume PCB manufacturing ensures that these devices are reliable, accurate, and safe.

● Wearable Health Monitors: Devices like heart rate monitors, ECG sensors, and glucose monitors use PCBs to process and transmit data, helping users track their health.

● Diagnostic Equipment: Medical imaging devices such as MRIs, CT scanners, and X-ray machines rely on PCBs to process signals and control their functions.

● Implantable Devices: High-volume PCBs are used in implantable devices like pacemakers and insulin pumps, which require consistent and reliable performance.

High-volume PCBs are integral to the rapidly growing field of industrial automation. These PCBs power robots, automation systems, and control units that streamline manufacturing processes.

● Robotics: Automated manufacturing lines use robotics to improve efficiency, and these robots rely on PCBs for motion control and power distribution.

● Programmable Logic Controllers (PLCs): PLCs are essential in industrial automation for controlling machinery. High-volume PCBs provide the necessary power management and control systems.

● Sensors and Actuators: These components rely on PCBs to monitor and control operations, ensuring that automation systems run smoothly and efficiently.

Industrial Sector | PCB Contribution |

Robotics | Power and signal management |

PLCs | Control and automation |

Sensors and actuators | Signal processing and control |

As electronics continue to evolve, so do the technologies used to produce them. High-volume PCB manufacturing is continuously improving to meet the growing demands for smaller, more efficient, and more sustainable devices.

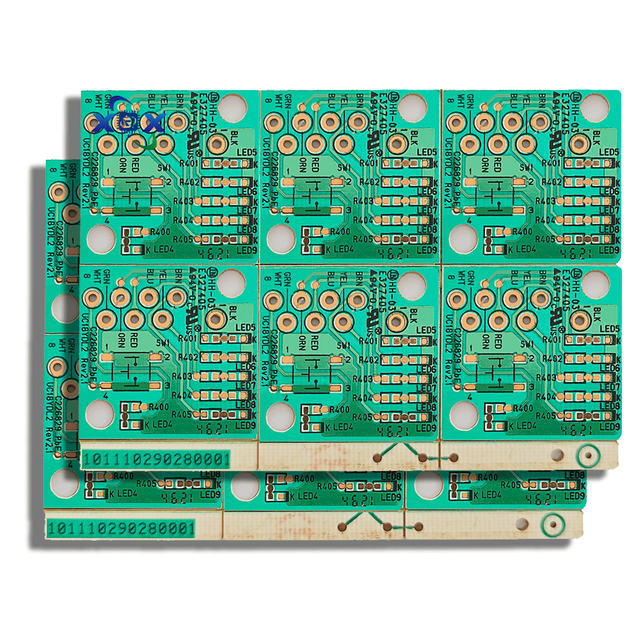

Advancements in PCB technology have led to the development of smaller, more powerful, and highly integrated designs. High-density interconnect (HDI) and multi-layer PCBs are now common, allowing for more components to be packed into smaller spaces.

● Multi-layer PCBs: These PCBs allow for increased functionality in compact designs, making them ideal for modern smartphones and wearables.

● HDI PCBs: High-Density Interconnect (HDI) PCBs enable finer traces and higher component density, which is crucial for creating smaller and more powerful devices.

As sustainability becomes a growing concern, high-volume PCB manufacturers are embracing environmentally friendly practices to minimize their environmental impact.

● Lead-free PCBs: The shift toward lead-free PCBs is a significant step toward meeting global environmental standards such as RoHS.

● Energy-efficient production: Manufacturers are adopting energy-efficient techniques to reduce power consumption during the production process.

● Recyclable PCBs: Designing PCBs for recyclability is another key trend, which helps reduce electronic waste.

High-volume PCB manufacturing is essential for a range of industries, providing significant cost savings, enhanced quality control, and faster production timelines. With companies like Dongguan Xinrongxing Technology Co., Ltd. leading the way, their advanced PCB solutions ensure consistent reliability and optimal performance. Their products support industries from consumer electronics to automotive, delivering value through precision manufacturing.

A: High-volume PCB manufacturing refers to the large-scale production of printed circuit boards, which are essential components in electronic devices. This process allows for consistent, cost-effective production.

A: It reduces costs by utilizing economies of scale, allowing for bulk material purchases and minimizing the per-unit cost of each PCB.

A: Industries such as consumer electronics, automotive, medical devices, and industrial automation rely on high-volume PCB manufacturing for their electronic components.

A: Quality control ensures the reliability and performance of PCBs, which are critical for the proper functioning of electronic devices in various applications.

A: It speeds up production cycles by using automated processes, allowing manufacturers to meet tight deadlines and deliver products faster.