close

Choose Your Site

Global

Social Media

Views: 0 Author: Site Editor Publish Time: 2026-01-15 Origin: Site

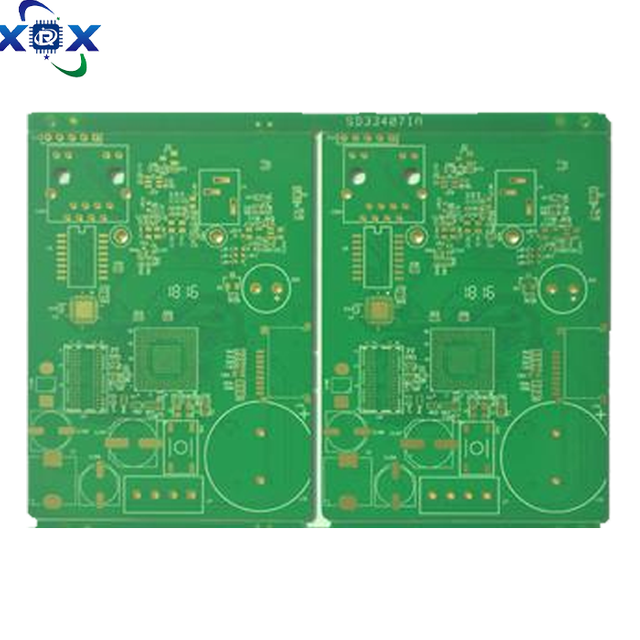

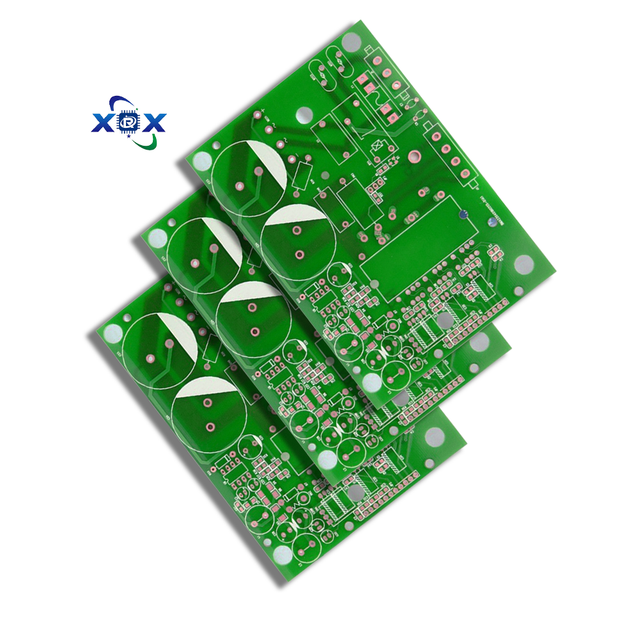

Have you ever wondered how barebone PCBs can speed up your prototyping process? Barebone PCBs are key in testing and refining designs before full-scale assembly. In this guide, we’ll explore what barebone PCBs are and how they impact your design process. You’ll learn how they can save you time and costs while optimizing your PCB designs.

Barebone PCBs are printed circuit boards (PCBs) that are manufactured with the necessary traces, pads, and vias but without any components soldered onto them. These boards are essentially “empty” but ready to be populated with components as needed. Their primary use is in the early stages of prototyping, where designers can test the basic structure and connectivity before committing to the full assembly.

● Cost-Effectiveness: Barebone PCBs are cheaper to produce than fully assembled boards, as they eliminate the cost of component soldering.

● Speed: Using barebone PCBs allows for faster prototyping and testing of circuit designs.

● Flexibility: They offer flexibility to test various components or modify the design without investing in fully assembled PCBs.

When designing a Barebone PCB, several key considerations should be taken into account to ensure the final design works as intended:

● Trace Width and Spacing: Proper trace width and spacing are crucial for electrical performance and manufacturing ease.

● Layer Count: Depending on the complexity of your circuit, you may need to choose between single-layer or multi-layer barebone PCBs.

● Component Placement: Although no components are installed, planning for where components will be placed can make the transition to a fully assembled PCB smoother.

Factor | Considerations |

Trace Width | Proper width prevents overheating and ensures signal integrity. |

Layer Count | More layers allow for more complex designs but increase cost. |

Component Placement | Plan for future component connections to avoid layout issues. |

Barebone PCBs play an integral role in optimizing circuit design. By enabling rapid testing and modification, they help engineers identify and resolve design flaws before moving to a fully assembled board. This optimization helps prevent costly mistakes that could arise during the assembly phase.

Creating a barebone PCB involves several steps, each requiring precise attention to detail. The process typically follows these stages:

1. Designing the PCB Layout: Using software tools like Eagle or KiCad, the design is mapped out digitally, including the placement of traces, pads, and vias.

2. Fabrication of the PCB: Once the design is complete, the PCB is manufactured, typically involving processes like etching the copper traces onto the substrate.

3. Testing and Inspection: After fabrication, the bare PCB undergoes an electrical test to verify that the basic connections are in place before moving on to the assembly stage.

● Materials: The choice of substrate material, such as FR4 or other high-quality options, impacts the durability and performance of the PCB.

● Precision: Accurate manufacturing processes ensure the proper alignment of traces and vias, which is essential for the board's functionality.

● Surface Finish: The surface finish of the PCB, such as HASL (Hot Air Solder Leveling), impacts the solderability and overall quality.

Barebone PCBs significantly reduce costs in the early stages of prototyping. Since they are not fully assembled, you are only paying for the PCB itself, without the additional cost of components. Furthermore, the simplicity of barebone PCBs allows for faster turnarounds, meaning prototypes can be tested and iterated in less time.

Advantage | Description |

Lower Costs | No need for components, reducing upfront expenses. |

Faster Turnaround | Quick production times allow rapid testing and adjustments. |

More Iterations | Lower cost and faster prototyping encourage multiple iterations. |

With barebone PCBs, engineers and designers have complete flexibility to test a wide range of components and configurations. This makes them ideal for innovative designs and new projects that require flexibility in testing before committing to a full design.

● Trace Issues: Incorrect trace width or poor routing can lead to circuit failures or signal integrity problems.

● Via Problems: Improper via placement or size can lead to connection issues.

● Power Distribution: Ensuring power is distributed evenly across the board can be challenging in complex designs.

Testing a barebone PCB is essential for identifying potential issues before moving forward. Common testing methods include:

● Continuity Testing: Ensures that all traces are properly connected.

● Signal Integrity Testing: Verifies that the PCB can handle the necessary signals without degradation.

● Thermal Testing: Ensures that the board does not overheat during operation.

Choosing the right manufacturer for your barebone PCBs involves considering several key factors:

● Experience and Reputation: Look for manufacturers with a proven track record in producing high-quality PCBs, particularly barebone versions, which require specialized attention to detail. A well-established manufacturer will have the expertise to meet your design specifications and guide you through the prototyping process.

● Manufacturing Capabilities: Different manufacturers may specialize in specific types of PCBs or offer a variety of options. Make sure the manufacturer can produce the required type of barebone PCBs, such as single or multi-layer boards, and is capable of handling the complexity of your design.

● Quality Control: Reliable PCB manufacturers implement strict quality control processes to ensure that each PCB meets industry standards. Make sure the manufacturer uses state-of-the-art testing and inspection tools, such as Automated Optical Inspection (AOI) and Electrical Test (ET), to guarantee high-quality production.

Factor | Consideration |

Experience | Proven expertise in PCB production. |

Manufacturing Capabilities | Ensure they can handle your design complexity. |

Quality Control | Rigorous testing methods for consistent quality. |

Lead Time | Fast production and timely delivery for prototypes. |

Price Competitiveness | Cost-effective without compromising quality. |

Dongguan Xinrongxing Technology Co., Ltd. is a trusted manufacturer that specializes in high-quality barebone PCBs. With years of experience in the PCB industry, they understand the unique requirements for prototyping and offer top-notch services, ensuring that your designs are not only functional but also reliable. Their manufacturing process adheres to the highest standards, from the initial design phase to the final testing.

Tip: Partnering with a reputable manufacturer like Dongguan Xinrongxing Technology Co., Ltd. ensures your barebone PCBs are produced with the highest level of precision, which is critical for efficient prototyping.

● Customer Support: A reliable manufacturer should provide excellent customer service, from design assistance to technical support. This ensures that you can resolve any issues quickly during the prototyping phase.

● Scalability: Consider whether the manufacturer can scale production if the prototype proves successful. Choosing a supplier who can handle both small-volume prototyping and large-scale production ensures smoother transitions as your product moves from prototype to mass production.

● Cost-Effectiveness: While quality is critical, cost is also a significant factor. Compare prices from different manufacturers, but be wary of choosing the cheapest option at the expense of quality. The long-term costs of poor-quality PCBs can be far higher than a slightly more expensive but reliable manufacturer.

Barebone PCBs are essential for efficient prototyping and design. By using them, you can quickly test and refine your circuits, saving both time and money. Dongguan Xinrongxing Technology Co., Ltd. offers high-quality barebone PCBs that help streamline the prototyping process, ensuring your designs meet industry standards with precision. Their reliable products and services are perfect for rapid iteration in any PCB design project.

A: A Barebone PCB is a circuit board without components, featuring only the essential traces, vias, and pads for prototyping purposes.

A: Barebone PCBs are used to test circuit layouts and connections before full assembly, allowing for fast and cost-effective design validation.

A: Barebone PCBs help speed up the testing process, reduce costs, and allow for quick iterations in the early stages of design.

A: Barebone PCBs are generally cheaper than fully assembled PCBs, as they don't include components or soldering.

A: To troubleshoot Barebone PCBs, check for continuity, test signal integrity, and ensure correct trace width and spacing.