close

Choose Your Site

Global

Social Media

Views: 0 Author: Site Editor Publish Time: 2026-01-15 Origin: Site

Are you curious about how BGA technology enhances PCB boards? Ball Grid Array (BGA) packaging is a game-changer for high-performance electronic devices. In this article, we will dive into the world of BGA, exploring how it works, its advantages, and its applications in modern technology. You will learn how BGA integration into PCB boards enables improved signal integrity, space efficiency, and thermal management, driving the evolution of devices like smartphones, medical equipment, and telecom infrastructure.

Ball Grid Array (BGA) is a surface-mount packaging technique where the integrated circuit (IC) is soldered onto a printed circuit board (PCB) using an array of small solder balls that replace traditional pins. Unlike other packaging methods such as Dual Inline Packages (DIP) or Surface Mount Devices (SMD), BGA uses solder balls, which provide a higher pin count and better performance.

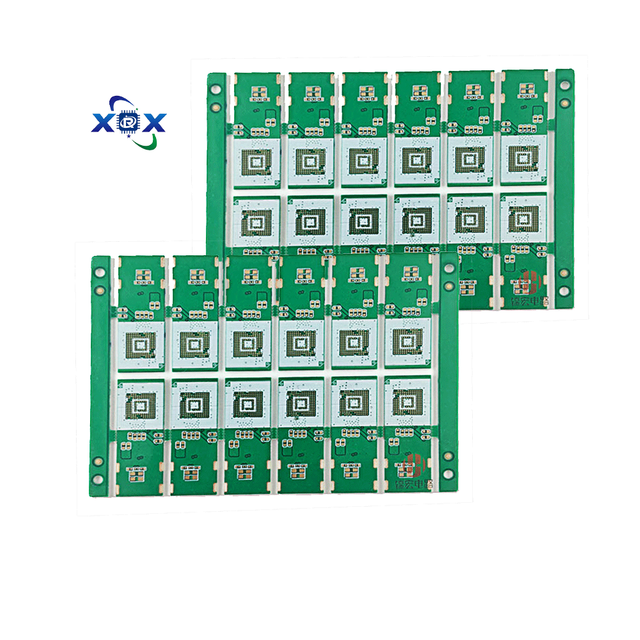

XRXPCB integrates BGA into their multi-layer PCBs, providing high-density solutions ideal for advanced applications that require compact, high-performance components.

BGA packages are mounted on a PCB through reflow soldering. In this process, the PCB is heated in a reflow oven, causing the solder balls on the BGA component to melt and form electrical connections between the IC and the PCB. This process ensures reliable and efficient connections.

BGA’s Impact: The key benefit of BGA is its ability to provide better signal integrity. Shorter electrical connection paths reduce the risk of interference, making it ideal for high-speed applications where precision and stability are essential.

BGA allows for significantly higher pin counts in a smaller space compared to traditional packages like DIP or QFP. The small size and high density of solder balls make it possible to accommodate more connections without increasing the component size. This is especially important in advanced applications such as mobile devices, where more functionality is required in a compact design.

XRXPCB’s multi-layer PCBs are designed to handle BGA packaging, supporting high-performance devices with complex connections.

The even distribution of solder balls in BGA packages enhances signal integrity. The layout ensures that electrical signals travel through shorter and more reliable paths, reducing resistance and capacitance. This leads to faster data transfer rates and more stable connections.

At XRXPCB, high-precision manufacturing equipment is used to ensure that BGA components are integrated accurately into PCBs, reducing the risk of defects and ensuring high-quality performance.

Thermal management is a crucial factor in modern electronics. BGA provides better heat dissipation compared to traditional lead-based packages. The solder balls in BGA act as a heat sink, dispersing heat evenly across the PCB and helping prevent overheating of components.

This feature is particularly useful for high-performance devices like microprocessors and memory chips, which generate substantial heat during operation. XRXPCB ensures that their BGA-integrated PCBs are designed for optimal thermal efficiency.

As electronics continue to shrink, BGA is key to achieving smaller and more efficient devices. The compact nature of BGA allows for miniaturization of PCBs without compromising on performance. This is especially beneficial for modern devices like smartphones, wearable technology, and laptops, where space is limited.

With BGA integration in multi-layer PCBs, XRXPCB enables clients to meet the demands of miniaturization while maintaining high performance.

BGA (Ball Grid Array) is more efficient than traditional packages like Dual Inline Package (DIP) and Surface Mount Technology (SMD). Here’s why:

● Higher Pin Count: BGA allows for more pins in a smaller footprint, making it ideal for high-performance devices that require more connections.

● Better Electrical Performance: The arrangement of solder balls in BGA ensures shorter electrical pathways, reducing signal loss and minimizing noise compared to leaded packages.

● Flexibility in PCB Design: XRXPCB specializes in creating PCBs that can support both BGA and other IC packages, offering clients flexibility in choosing the right package for their needs. This versatility is crucial for modern electronics where space, performance, and reliability are key factors.

When comparing BGA to Chip-on-Board (COB), the differences in design and application become more apparent:

● Mounting Method: COB involves directly mounting the chip onto the PCB without any packaging, which might seem more cost-effective but has limitations. On the other hand, BGA uses an IC package with solder balls, offering a more secure connection and robust performance.

● Reliability: BGA’s reliability stands out due to its more secure soldering connections. XRXPCB’s high-precision manufacturing process ensures the integrity of BGA connections, which is crucial in high-reliability applications like medical devices and automotive electronics.

● Use Case: BGA is preferred for high-performance devices that require greater reliability, such as in smartphones and medical devices, while COB is more suited for lower-cost, less complex designs.

The Standard BGA (S-BGA) is the most commonly used type. It offers a balanced solution between performance, size, and cost. With a standard grid of solder balls, S-BGA provides solid electrical connections and is widely used in devices like computers, smartphones, and telecommunications equipment.

Advantages:

Feature | Benefit |

High-density connections | Provides compact designs |

Reliable electrical and thermal performance | Ensures durability under high-demand conditions |

XRXPCB’s multi-layer PCBs are designed to accommodate S-BGA packages, providing reliable and cost-effective solutions for various applications.

For ultra-compact devices like mobile phones and wearables, Micro BGA (μBGA) is the go-to solution. These BGAs are much smaller than S-BGA but still retain the benefits of BGA, such as high performance and improved signal integrity. μBGA packages are often used in applications where space is at a premium, and performance cannot be compromised.

Applications:

● Mobile phones

● Wearable devices

● Ultra-compact electronics

XRXPCB can integrate μBGA into their PCBs, providing a miniaturized solution without sacrificing performance.

Flip-Chip BGA (FC-BGA) is a more advanced version of BGA technology where the IC chip is flipped upside down and soldered directly to the PCB. This method allows for better performance, as the signal path is shortened, and the heat dissipation is more efficient.

Advantages:

● Improved electrical performance

● Better heat dissipation

● Smaller form factor

XRXPCB is equipped to handle FC-BGA integration, offering clients the best possible solution for high-speed, high-performance applications.

● Chip-on-Board (COB): In this configuration, the IC is mounted directly onto the PCB without an external package, which can help reduce the overall size and cost of the device. However, the lack of packaging means that COB is more vulnerable to damage and heat issues.

● Package-on-Package (POP): This advanced technology involves stacking two or more ICs in a single package. POP is often used in applications requiring multiple chips in one package to save space, such as in smartphones and tablets.

Applications:

Application Area | Use Case |

High-performance mobile devices | Smartphones, tablets |

Compact computing systems | Space-efficient designs for computing |

XRXPCB provides a range of packaging options, including POP and COB, tailored to meet the specific needs of clients in consumer electronics, automotive, and telecommunications.

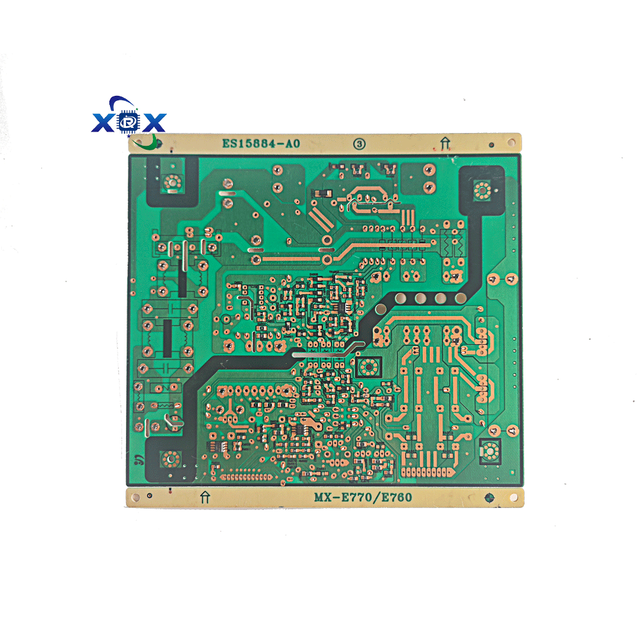

When designing PCBs for BGA integration, several factors must be considered to ensure the best performance of the component. Key design elements like trace width, via placement, and pad size are critical. These aspects ensure that electrical signals are transmitted effectively while minimizing potential issues like interference and signal degradation.

XRXPCB specializes in multi-layer PCB designs that are optimized for BGA components. Their expertise guarantees that all design considerations, including optimal trace width, pad size, and via design, are meticulously met to support the high-performance demands of BGA. This ensures that the BGA connections function at their highest capacity without compromising the PCB’s integrity.

The BGA soldering process involves reflow soldering, where the PCB and BGA component are heated in a controlled oven. This process causes the solder balls to melt, allowing the BGA to securely attach to the PCB. The precise melting and solidification of the solder balls form strong, reliable connections between the IC and the PCB.

XRXPCB’s expertise includes advanced soldering techniques tailored for high-performance products. This ensures that there are no defects in the BGA solder joints, maintaining the stability and reliability required in applications like medical devices and industrial control systems. The company’s focus on quality control during the soldering process guarantees that the BGA assemblies are fault-free, contributing to the long-term performance of the devices.

After the BGA soldering process, the next crucial step is inspecting and testing the solder joints to ensure their quality and reliability. Since BGA solder joints are hidden under the component, X-ray technology is typically used for inspection. This advanced method allows for the detection of potential issues, such as cold joints or voids that could affect performance.

At XRXPCB, each BGA assembly undergoes rigorous testing, including thermal cycling and electrical testing. Thermal cycling tests how well the assembly withstands temperature changes, simulating real-world conditions, while electrical testing ensures that the BGA connections provide stable and efficient power transmission throughout the device's operation.

BGA plays a vital role in consumer electronics, where devices need to be small, lightweight, and capable of handling high-performance tasks. Smartphones, laptops, and tablets commonly use BGA to improve the overall performance and space efficiency. The high-density connection made possible by BGA is crucial for devices that require more connections in a compact space.

XRXPCB’s PCBs support high-performance BGA integration for these types of consumer devices. Their multi-layer PCBs are designed to accommodate BGA components, ensuring that the devices perform efficiently while remaining compact.

In the automotive industry, BGA is used in components like ECUs (Electronic Control Units), infotainment systems, and autonomous driving systems. These systems require compact, reliable PCB designs, where BGA provides the space-efficient connections needed for high-speed communication between sensors, processors, and other crucial components.

XRXPCB’s expertise in BGA integration ensures that automotive PCBs can handle the high demands of these critical systems, offering performance, durability, and reliability for modern vehicles.

BGA is increasingly preferred in the medical field due to its robustness and reliability. Medical devices, such as diagnostic equipment, patient monitoring systems, and implantable devices, require precision in their electronic components. BGA offers the compactness and durability required in these high-stakes applications.

With its advanced PCB manufacturing capabilities, XRXPCB ensures that BGA components are securely integrated into medical devices, providing the reliability necessary for patient safety and high-performance medical systems.

The telecommunications industry relies on BGA to handle high-speed data transmission and networking equipment. Devices such as 5G equipment and telecommunication infrastructure benefit from BGA’s ability to provide higher pin counts and better signal integrity.

XRXPCB’s multi-layer PCB designs are ideal for these demanding telecom applications, where BGA ensures fast, reliable, and consistent connections across various network components.

In industrial automation, BGA is crucial due to its high-density connections and reliable performance in harsh environments. Whether in robotics, automated manufacturing systems, or power control, BGA provides the necessary electrical performance in compact, ruggedized designs.

XRXPCB’s capabilities in designing BGA-integrated PCBs ensure that industrial systems operate smoothly, offering both reliability and performance under demanding conditions.

When selecting the right BGA (Ball Grid Array) package for your PCB design, several factors need to be considered to ensure that the component meets the requirements of your application. Here are the key selection criteria:

● Pin Count: The number of pins in a BGA package determines how many connections can be made between the IC and the PCB. For high-performance applications, choose a BGA with a higher pin count for better functionality.

● Size: The size of the BGA package must align with the available space on the PCB. For compact devices, a smaller BGA package like Micro BGA (μBGA) might be necessary to save space without sacrificing performance.

● Thermal Management: BGA packages are known for their superior thermal efficiency, but the thermal requirements of your design must still be considered. A BGA with better heat dissipation properties will be crucial for high-power devices like automotive electronics or medical devices.

● Power Handling: Power dissipation is an important factor when choosing the right BGA. High-power applications require BGA packages that can handle greater electrical loads without overheating or causing failures.

XRXPCB offers custom solutions for selecting the right BGA based on your device's specific needs. They use their expertise in PCB design, assembly, and testing to ensure that the BGA chosen is perfectly integrated into the overall PCB design.

As technology continues to evolve, BGA technology is advancing to meet the needs of next-generation devices. New materials and manufacturing techniques are being developed to improve BGA performance:

● Better Heat Dissipation: Innovative materials that enhance the heat dissipation properties of BGA packages are being integrated into designs. This is especially important as electronic devices become smaller and generate more heat.

● Higher Data Transmission Speeds: With increasing demands for high-speed data transfer, BGA designs are being refined to handle higher bandwidths and faster communication speeds.

XRXPCB stays at the forefront of these advancements, continuously integrating the latest BGA technology into their PCBs to meet the performance standards of modern electronics.

As the demand for 5G networks, IoT (Internet of Things) devices, and AI (Artificial Intelligence) applications grows, BGA will continue to play a crucial role:

● 5G Networks: The high-speed, low-latency requirements of 5G networks demand efficient and compact components. BGA is ideal for 5G infrastructure due to its ability to support high-density connections and maintain signal integrity.

● IoT Devices: BGA will be essential in IoT devices that need to be compact, power-efficient, and reliable. Smaller BGA packages are perfect for wearable devices and connected home products.

● AI Applications: In AI hardware, where performance and processing power are key, BGA is used for high-performance ICs that power machine learning and neural networks.

XRXPCB designs PCBs that can meet the increasing demands of 5G, IoT, and AI, ensuring that BGA technology remains a critical component in these rapidly growing fields.

As sustainability becomes a key focus in electronics manufacturing, eco-friendly practices are being integrated into BGA and PCB manufacturing processes:

● Eco-Friendly Materials: The industry is shifting towards using environmentally friendly materials that reduce the environmental impact of BGA packaging and PCB production.

● Energy-Efficient Manufacturing: New methods are being developed to reduce the energy consumption during the PCB and BGA assembly processes, making them more sustainable.

● Recyclability: The future of BGA packaging includes using materials that can be more easily recycled at the end of the device’s lifecycle, promoting a circular economy.

XRXPCB is committed to sustainability by incorporating eco-friendly processes into their manufacturing, ensuring that their BGA-integrated PCBs are not only high-performance but also environmentally responsible.

BGA technology significantly enhances the performance and compactness of PCB boards. Dongguan Xinrongxing Technology Co., Ltd. specializes in high-precision BGA-integrated PCBs, providing solutions for consumer electronics, automotive systems, and medical devices. Their multi-layer PCBs offer reliable and efficient BGA integration, making them ideal for high-performance applications in modern technology.

A: Ball Grid Array (BGA) is a surface-mount packaging method where an integrated circuit is soldered to a PCB using small solder balls arranged in a grid pattern, improving signal integrity and reliability.

A: BGA improves PCB performance by providing higher pin counts, better electrical connections, and more efficient thermal management, which is essential for high-performance devices.

A: BGA is chosen for its compact size, high-density connections, and enhanced signal integrity, making it ideal for devices requiring compact and reliable performance, like smartphones and medical equipment.

A: BGA can be used in multi-layer PCBs, offering high-density connections. However, it is not suitable for all applications, especially those that don’t require high-performance components.

A: The advantages of BGA over traditional packages include a smaller footprint, higher pin count, better thermal efficiency, and superior signal integrity, which enhances overall device performance.