close

Choose Your Site

Global

Social Media

Views: 0 Author: Site Editor Publish Time: 2025-09-29 Origin: Site

You see printed circuit board design everywhere, from your phone to your TV. Display PCB design shapes the way electronics work and look. Choosing the right pcb can boost your device’s performance. Each pcb type has its own strengths. When you understand these differences, you make better choices for your project. Xinrongxing leads the industry with quality pcb solutions. You get reliable results when you work with experts who care about every pcb they make.

Tip: Picking the right pcb can make your electronics more powerful and long-lasting.

Knowing different PCB types helps you pick the best one. Each type has special features that change how well it works and how long it lasts.

Good PCB design needs careful planning. You should think about where to put parts, how to connect them, and how to handle heat. This helps your PCB work well for a long time.

Signal integrity is very important for display quality. Keep signals strong by using the right layer order and lowering noise.

Thermal management stops your device from getting too hot. Use things like metal-core PCBs to spread heat and keep your device safe.

Working with experts like Xinrongxing gives you good help and support. They offer custom choices and deliver your PCBs on time.

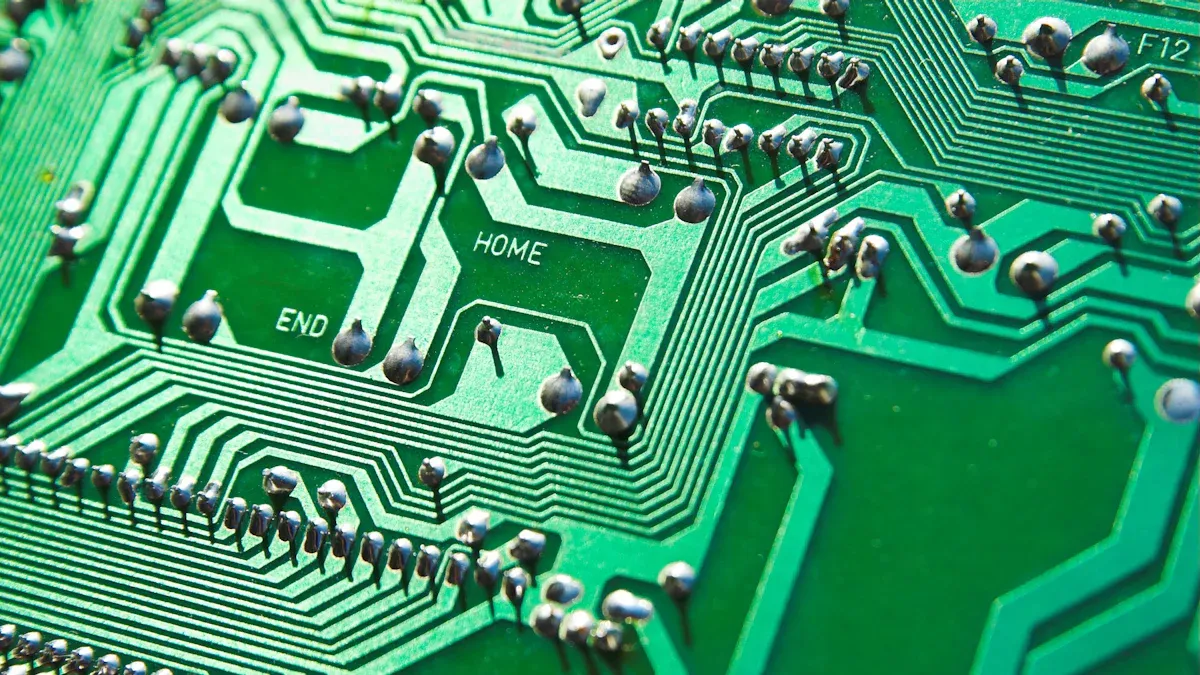

You see a pcb in almost every electronic device you use. A printed circuit board connects and supports all the electronic parts inside your gadgets. It looks like a thin, flat board with lines and pads made of copper. These lines act like tiny roads, letting electricity travel between different parts. When you turn on your phone or computer, the pcb makes sure everything works together.

A pcb can have one layer or many layers stacked together. Some boards are simple, while others are very complex. The type of pcb you need depends on your project. If you want your device to work well and last a long time, you must choose the right printed circuit board.

Designing a pcb takes careful planning. You start by thinking about what your device needs to do. Next, you draw a map called a schematic. This map shows how each part connects. After that, you lay out the pcb, placing each part in the best spot.

Here are some important steps you follow in pcb design:

Component Placement: You put each part where it works best. Good placement helps your pcb run smoothly and makes testing easier.

Routing Traces: You draw the copper lines that connect everything. Avoid sharp corners to keep signals strong.

Thermal Management: You space out parts that get hot. This keeps your pcb cool and safe.

Design Rules Check: You follow rules for spacing and layout. This helps your pcb work well and makes it easier to build.

Tip: Always keep high-speed lines away from sensitive areas. This reduces noise and keeps your pcb reliable.

PCB design for displays brings extra challenges. Take a look at some common ones:

Challenge | Description |

|---|---|

PCB Layout Complexity | More features mean more complex pcb layouts. |

Miniaturization | Smaller parts make the pcb harder to design and build. |

High-Speed Data | Fast signals need careful routing to avoid signal loss. |

Heat Dissipation | More power means your pcb must handle extra heat. |

Manufacturing Constraints | You must design your pcb so it can be made easily and at a good cost. |

If you follow industry standards, your pcb will be easier to test and upgrade. Always keep enough space between parts and away from the edges. This prevents problems like electrical arcing and keeps your printed circuit board safe.

There are many kinds of pcb in electronics. Each one is good for different jobs. Picking the right pcb helps your project work well and last longer. Xinrongxing has many pcb types, like FR-4 double-sided pcb, aluminum pcb, and keyboard pcb. Every board gives you good quality and works well.

This is the easiest pcb type to use. A single-sided pcb has copper on one side and parts on the other. You find this pcb in simple electronics. It is good for easy circuits and saves money.

Here are some places you see single-sided pcb:

Application Type | Description |

|---|---|

Electronic Timers | Used in kitchen tools like microwaves for simple timers. |

Smoke Detectors | Connects sensors and alarms in home smoke detectors. |

Basic Motor Controllers | Controls motor speed and direction in small machines. |

LED Strip Lights | Makes cheap and cool designs for LED lights. |

Low-Power LED Bulbs | Connects a few LEDs to a driver circuit. |

Power Supplies | Used in low and medium power things like phone chargers. |

Automotive Interior Lights | Helps low-power LEDs in car dashboards or dome lights. |

Basic Sensor Modules | Finds open or closed states in car systems. |

You see single-sided pcb in many things you use every day. It is simple to make and quick to build. The market for single and double-sided pcb was about $15 billion in 2022 and is still growing. This type uses easy pcb trace technology, but you cannot make hard circuits with it.

You use double-sided pcb when you need more connections. This pcb has copper on both sides. Vias connect the traces from one side to the other. You get more ways to design and can fit more parts in less space.

Here is how double-sided pcb is different from single-sided pcb:

Feature | Single-Sided PCBs | Double-Sided PCBs |

|---|---|---|

Cost | Cheaper | Costs more because of extra layer |

Design Complexity | Easier to design and make | Harder to design and put together |

Reliability | Very reliable with fewer problems | Can have signal problems if not designed well |

Design Flexibility | Not many ways to route | More ways to route |

Board Size | Needs a bigger board | Smaller board because of two layers |

Performance | Not as good for fast signals | Better for fast signals |

You see double-sided pcb in adapters, audio gear, and office machines. Xinrongxing’s FR-4 double-sided pcb is special because it does not catch fire easily and is strong. You get better pcb trace technology and more ways to design your board.

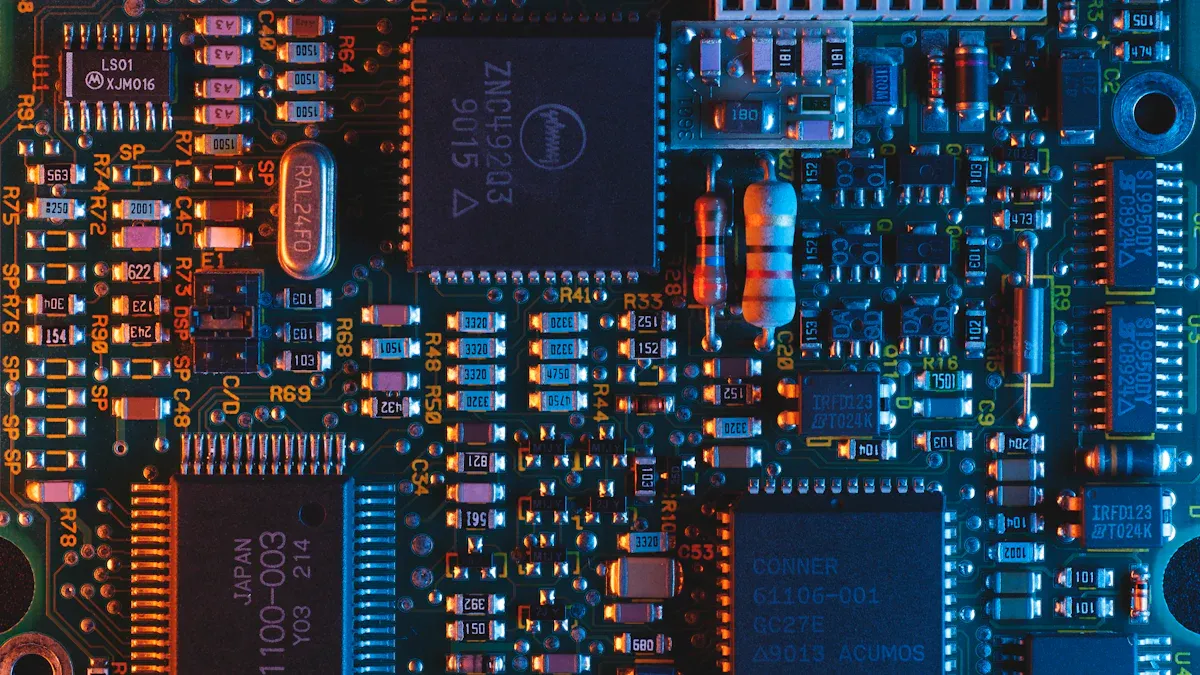

You pick multilayer pcb for high performance and lots of connections. This pcb stacks three or more copper layers with insulation between them. You get special power and ground planes that help signals stay strong and cut down on noise.

Here is a quick look at the types of pcb:

PCB Type | Construction | Routing | Advantages | Limitations |

|---|---|---|---|---|

Single-Layer | One copper layer on a base | All traces on one side | Cheapest, easiest to design | Not good for hard circuits, few parts |

Double-Layer | Copper on both sides, joined by vias | Two sides for routing | Not too expensive, more parts fit | Harder to make |

Multilayer | Three or more copper layers | Hard routing, power planes | Fits most parts, best performance | Costs more, harder to design |

Multilayer pcb makes up over 43% of the market by volume. You see this pcb in phones, computers, and smart machines. New pcb trace technology lets you make small, strong devices. You get better signals and can use many connectors. New ways to make pcb help lower the price and make them more exact.

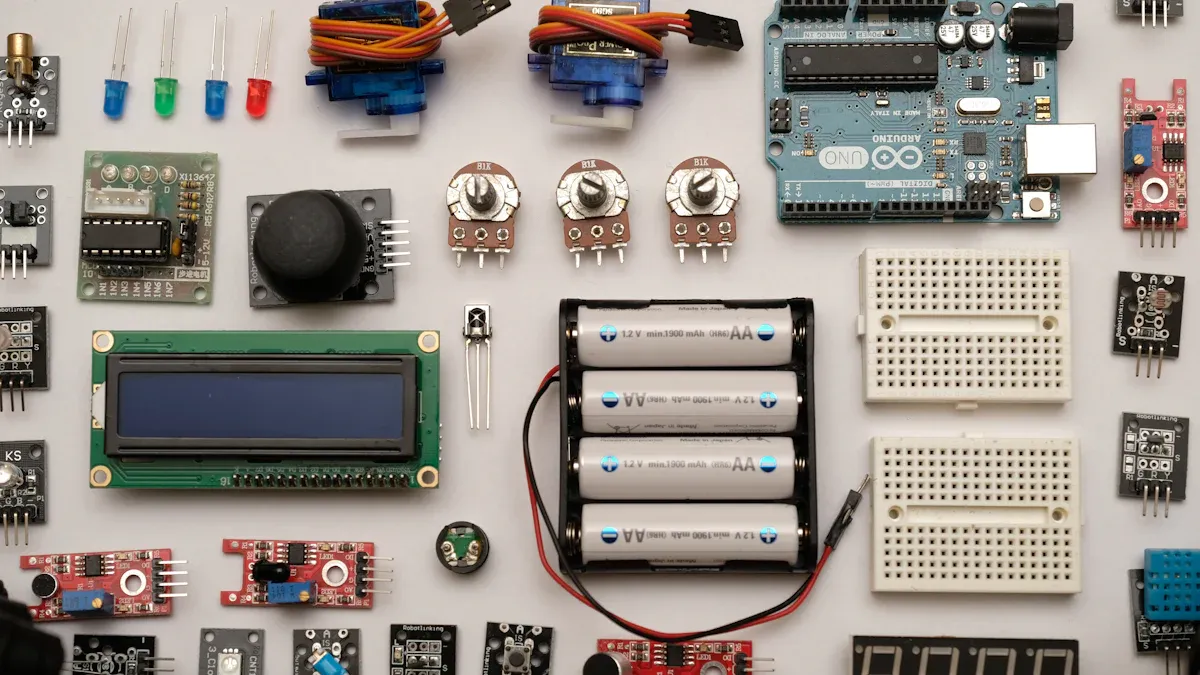

Some pcb types are made for special jobs. Xinrongxing has aluminum pcb and keyboard pcb, each with special things they do.

Aluminum pcb: You use this pcb for LED lights and power electronics. It handles heat well and keeps things cool.

Keyboard pcb: You can choose soldered or hot-swappable types. Soldered pcb gives strong and steady connections. Hot-swappable pcb lets you change switches fast, which is great for keyboard fans.

Here is a quick look at special pcb types:

Type | Features | Advantages | Best Use Cases |

|---|---|---|---|

Aluminum PCB | Great at handling heat | Stays cool, lasts long | LED lights, power electronics |

Soldered Keyboard PCB | Switches are soldered on | Strong, steady connections | Cheap builds, lasts a long time |

Hot-Swappable Keyboard PCB | Switches in sockets, no soldering needed | Easy to change, fix fast | DIY, testing switches, fans |

Gaming & RGB PCB | Has RGB lights, fast switches | Quick response, looks cool | Gaming, fast keyboards |

You see these special pcb types in lights, keyboards, and gaming gear. Xinrongxing has all these types, so you can find the right pcb for your project.

Tip: When you look at pcb types, think about what you need, how much you want to spend, and how well it should work. The right pcb type helps your device work better and last longer.

You want your electronics to work well and last long. Xinrongxing’s FR-4 double-sided pcb helps with this. This pcb uses strong FR-4 material. It can handle heat and tough use. Your devices stay safe and work better.

Here is why this pcb is special:

Feature | Benefit |

|---|---|

Improved Thermal Management | Your device stays cool and works longer. |

Signal Integrity | Shorter traces keep signals strong and clear. |

Increased Routing Capacity | You can add more parts on both sides. |

Interleaved Wiring | Complex connections are easier and more efficient. |

This pcb lets you use both sides for parts. You save space and add more features. It also helps control heat. Your electronics stay safe even when working hard.

Tip: If your project needs more power or speed, pick a double-sided pcb. You get more design choices and better results.

You see Xinrongxing’s FR-4 double-sided pcb in many things. It works in consumer electronics like smartphones and tablets. It is also used in cars where reliability is important. Factories use this pcb in control systems for tough jobs.

Here are some ways this pcb is used:

Consumer electronics: TVs, audio systems, smart devices

Automotive electronics: dashboards, sensors, control units

Industrial control: factory machines, automation equipment

Office devices: printers, copiers, adapters

This pcb fits many needs. Xinrongxing checks every pcb for quality. You can trust your devices to work well. If you need a special pcb, Xinrongxing can help you make it.

Note: When you choose a pcb from Xinrongxing, you get help from experts who care about your project.

When you look at a pcb, the base is called the substrate. The substrate gives the board its strength and shape. Picking advanced materials for the substrate changes how your pcb works. It also affects how long your pcb lasts. You need to choose the right substrate for your project. This is important if you want your display to work well.

Here are some advanced materials used in pcb construction:

FR-4: This is the most common material. It costs less and gives good insulation. You can use it for many pcb projects. It does not work well with high-frequency or high heat.

Ceramic: Ceramic is good for high-frequency signals. It has low loss and helps with heat. You see it in high-power or advanced display electronics.

Polyimide: Polyimide is strong and flexible. It works well in tough places like cars or airplanes.

PTFE: PTFE is great for high-frequency pcb jobs. It keeps signals clear. It costs more and is harder to make.

Metal Core: Metal core helps get rid of heat fast. You find it in LED lights and high-power electronics.

Here is a table to compare these advanced materials:

Substrate Material | Advantages | Applications |

|---|---|---|

FR-4 | Cheap, stable, flat | General pcb uses |

Ceramic | Low loss, good with heat | High-frequency, high-power pcb |

Polyimide | Flexible, handles heat | Aerospace, automotive, computing |

PTFE | Great for high frequencies | RF, microwave pcb |

Metal Core | Removes heat quickly | LED, high-power electronics |

Tip: Match your advanced materials to your pcb’s job. The right choice gives better performance and longer life.

Stacking layers in a pcb changes how your display works. Advanced materials in each layer help you get good results. A simple pcb has one or two layers. Advanced display systems need more layers.

Multilayer pcb gives better signal integrity and power distribution. It also cuts down on interference. This keeps your display clear and fast. If you organize layers well, you can route high-speed signals easily. This matters for displays that move lots of data.

Here is what a good layer structure does for your pcb:

Makes signals strong so your display looks sharp.

Spreads power evenly for better reliability.

Cuts down on interference, so you get less noise.

Uses controlled impedance to keep signals steady.

Advanced materials and smart layer design work together. They help your pcb do hard jobs and keep your display working well.

Display pcbs are in many things you use every day. Your phone, tablet, and smartwatch all need a pcb to work. These boards link small parts and help your devices run fast. When you play games or watch TV, the pcb keeps things working right. Xinrongxing gives pcbs to big brands like Huawei and Xiaomi. This means you get good quality. You see these pcbs in smart bulbs, computers, and entertainment systems. They help give you bright screens, clear sound, and quick actions.

Tip: When you use your favorite gadget, remember a pcb is inside making it work.

Display pcbs are used in cars, factories, and control rooms. These boards must work in hard places. They face heat, cold, shaking, and bumps every day. Xinrongxing’s pcbs follow strict rules for safety and reliability. Automotive pcbs use special materials to stop water and heat damage. Good thermal management keeps car dashboards and sensors working well. In factories, pcbs help machines work safely and smoothly. Here is a table that shows what helps make them reliable:

Standard | Purpose | Impact on Reliability |

|---|---|---|

ISO 26262 | Checks safety and stops hazards | Makes failures less likely |

IPC-6012DA | Sets rules for making and testing | Helps boards work the same every time |

AEC-Q100/200 | Tests parts under stress | Shows they work even when pushed hard |

You want your industrial and automotive pcbs to fit parts easily and follow EMC rules. This helps control electromagnetic emissions. It keeps your systems safe and working well.

Display pcbs are in coffee makers, fridges, and microwaves. Your TV, wireless router, and game console all use a pcb. In offices, printers, scanners, vending machines, and network gear need these boards. PCBs help your devices work smarter and save energy. You get easy controls, bright displays, and steady performance. Xinrongxing works with big brands, so you get pcbs that last a long time.

Some office and home devices with pcbs:

Monitors

Wireless mice

Fax machines

Smart home appliances

PCBs are in many things you use every day. They help your devices work better and make your life easier.

When you make a display pcb, you want signals to move fast and clear. Signal integrity means signals stay strong as they travel on the board. If you do not care about signal integrity, your display may flicker or show mistakes. Good pcb engineering always puts signal integrity first.

Here are some important things to think about for signal integrity:

Design Consideration | Description |

|---|---|

Layer Arrangement | Put signal layers next to ground or power planes for steady paths. |

Ground Planes | Add more ground planes to lower noise and help EMI shielding. |

Symmetry | Keep your stack-up even to stop bending when making the pcb. |

You can also:

Use simulation tools to find problems like crosstalk and reflections before building your pcb.

Try backdrilling to get rid of extra via stubs and keep signal integrity high.

Pick low-loss materials for better impedance control and less signal loss.

A strong power delivery network helps signal integrity too. Put different decoupling capacitors close to fast parts. This keeps voltage steady and helps signal integrity. In pcb engineering, you check signal integrity at every step.

Tip: If you want your display to look good, always check signal integrity in your design.

Thermal management keeps your pcb cool and safe. If your display pcb gets too hot, it can break or slow down. Good thermal management spreads heat out and moves it away from hot spots. You need smart pcb engineering to get thermal management right.

Try these thermal management ideas:

Use metal-core pcbs for better heat flow, especially with LEDs.

Put hot parts in smart places to spread heat evenly.

Add heat sinks to pull heat away from your pcb.

Use fans or liquid cooling for big, hot displays.

Pick thermal interface materials to help heat move from parts to cooling tools.

The material you pick matters for thermal management. FR-4 does not move heat well, so it is good for low-power jobs. Metal-core pcbs, like aluminum, move heat much better. In pcb engineering, you plan thermal management early. This keeps your display working well.

Note: Good thermal management helps your display pcb last longer and work better.

You want your pcb to be easy to make and work every time. Manufacturing constraints shape your design choices. If you miss these, your pcb might have problems like cracks or layers coming apart.

Watch out for these manufacturing constraints:

Hard designs can make your pcb tough to build.

The material you pick affects both signal integrity and thermal management.

Quality standards keep your pcb safe and reliable.

Technical problems can slow down making your pcb.

Supply chain issues and material shortages can delay your project.

Environmental rules change how you make your pcb.

In pcb engineering, you balance signal integrity, thermal management, and manufacturing constraints. Smart design choices help you avoid problems and get the best results.

Remember: The best display pcb comes from careful planning and strong pcb engineering.

You want your display to work perfectly. The first step is to match your pcb to your application needs. Every project is different. You need to look at your LCD’s specifications. Check the interface type. Is it LVDS, RGB, or HDMI? Look at the resolution and size. Make sure your pcb fits the display you want.

You also need to think about voltage and power. Some displays need more power. Others use less. Your pcb must handle these needs. If you use flexible pcbs, you get more options for shape and size. Flexible pcbs bend and twist. You can fit them into tight spaces. This helps with circuit design in small devices.

Here’s a simple checklist to help you choose:

Check your LCD’s interface type.

Confirm the resolution and size.

Review voltage and power needs.

Pick the right controller IC.

Make sure the connectors match.

Plan for signal routing.

Add power management circuits.

Include backlight control.

Think about temperature and durability.

Tip: Flexible pcbs work great in wearables, foldable phones, and curved screens. You get more freedom in your circuit design.

You want your display to run fast and stay reliable. Performance matters. Cost matters too. You need to balance both. The materials you pick for your pcb change how well your display works. If you use flexible pcbs, you get better signal fidelity and thermal stability. This means your display looks sharp and lasts longer.

Flexible pcbs cost more than regular boards. You pay extra for advanced features. If your project needs high speed or lots of power, you may need a flexible printed circuit board. This type gives you better performance. You need to decide if the extra cost is worth it.

Here’s a table to help you compare:

PCB Type | Performance Level | Cost Range | Best Use Cases |

|---|---|---|---|

Single-sided pcb | Basic | Low | Simple gadgets |

Double-sided pcb | Medium | Medium | Audio, adapters, office devices |

Multilayer pcb | High | High | Phones, computers, smart tech |

Flexible pcbs | Very High | Highest | Wearables, foldables, curved displays |

You need to clarify your performance needs. If you want top speed and reliability, flexible pcbs are the best choice. If you want to save money, single or double-sided boards work fine for basic jobs.

Note: Advanced circuit design often means higher costs. Plan your budget before you choose your pcb.

You want a partner who understands your needs. Xinrongxing helps you every step of the way. You get reliable delivery. Xinrongxing has a perfect record. You can trust your pcb will arrive on time.

Xinrongxing keeps clients happy. Many customers come back again and again. You get strong support and expert advice. If you need flexible pcbs, Xinrongxing can make custom designs for you. You get help with circuit design and layout. The team listens to your ideas and turns them into working products.

Here’s why working with Xinrongxing makes sense:

You get reliable delivery every time.

You build a long-term partnership.

You get custom solutions for flexible pcbs and other types.

You work with experts who care about your project.

You get support from start to finish.

�� When you choose Xinrongxing, you get more than just a pcb. You get a team that wants your project to succeed.

Flexible pcbs open new doors for your display projects. You can create shapes and designs that were impossible before. Xinrongxing helps you use flexible pcbs in smart ways. You get better circuit design and more options for your devices.

When you understand different pcb types and design steps, your projects work better and last longer. Here’s why it matters:

You pick the right parts and place them well.

You follow rules that make building easier.

You keep signals clear and control heat.

You use a good plan for top results.

Xinrongxing supports you with expert help at every stage:

Description | |

|---|---|

Custom PCB Design | Get designs made just for your needs. |

Manufacturing | Reliable production for any project size. |

Maintenance | Keep your boards working their best. |

After-sales Support | Friendly help and answers when you need them. |

Ready to start your next project? Reach out to Xinrongxing for custom solutions and friendly support.

Single-sided PCBs have copper on one side. Double-sided PCBs have copper on both sides. You get more space for parts and better performance with double-sided boards.

You should look at your device’s needs. Think about size, speed, and power. If you need more features, pick double-sided or multilayer PCBs. Xinrongxing can help you decide.

Xinrongxing uses strict quality checks. You get reliable boards every time. Big brands like Huawei and Xiaomi trust Xinrongxing. You can count on friendly support and fast delivery.

Yes! You can ask for custom shapes, sizes, or features. Xinrongxing’s team listens to your ideas. You get a board that fits your project perfectly.

Xinrongxing uses FR-4, aluminum, and other advanced materials. You get strong boards that last. Each material works best for different jobs, like handling heat or making flexible designs.