close

Choose Your Site

Global

Social Media

Views: 0 Author: Site Editor Publish Time: 2025-09-18 Origin: Site

Choosing the best pcb circuit board supplier helps your project work better. It also makes your project more reliable. You need a partner who knows a lot about technology. They should have strong skills and experience. They must check quality very carefully. They should have a good supply chain for parts. It is important that they can make many boards if needed. Xinrongxing is a trusted printed circuit board maker. They use advanced technology. They do careful quality checks. They give great customer support for every pcb need.

Technical capabilities and expertise

Quality assurance processes

Reliable supply chain and sourcing

Manufacturing capacity and scalability

Pick a supplier who knows a lot and has done this work before. This helps you get good help for your project. - Find a supplier who checks their work well. This makes sure every PCB is good enough for you. - Choose a manufacturer who can help with design, assembly, and testing. This makes your project easier. - Make sure your supplier tells you all the prices. This helps you not miss any costs and plan your money well. - Good customer support and talking with you is important. This helps fix problems fast and keeps your project going.

When you pick a pcb manufacturer, you want a team that knows the industry well. If a company has many years of experience, they can handle lots of problems. Most trusted suppliers have worked in engineering for 7 to 9 years. This means they know how to fix issues and learn new technology. You should see if the supplier has been in the pcb circuit board business for a long time. A good supplier has people who can design and make boards. This helps them know what you need and give you good products.

A strong project portfolio shows what a pcb manufacturer can do. Trusted suppliers often show their work in many areas. You should look for projects in things like electronics, cars, or machines. This shows the supplier can do many kinds of pcb jobs. When you look at a portfolio, check for these skills:

Solving hard layout problems

Reading circuit plans and datasheets

Using pcb design programs

Making multilayer stackups

Measuring and soldering for tests

These skills show the supplier knows how to help your project from start to finish.

Xinrongxing is a trusted pcb maker with lots of skill and experience. They have worked with big brands like Huawei, ZTE, Xiaomi, and TCL. Xinrongxing’s team uses years of engineering knowledge on every job. They use advanced tools and check quality very carefully. You can trust Xinrongxing as one of the best suppliers in the field. Their long history and big client list show they always do great work on every pcb they make.

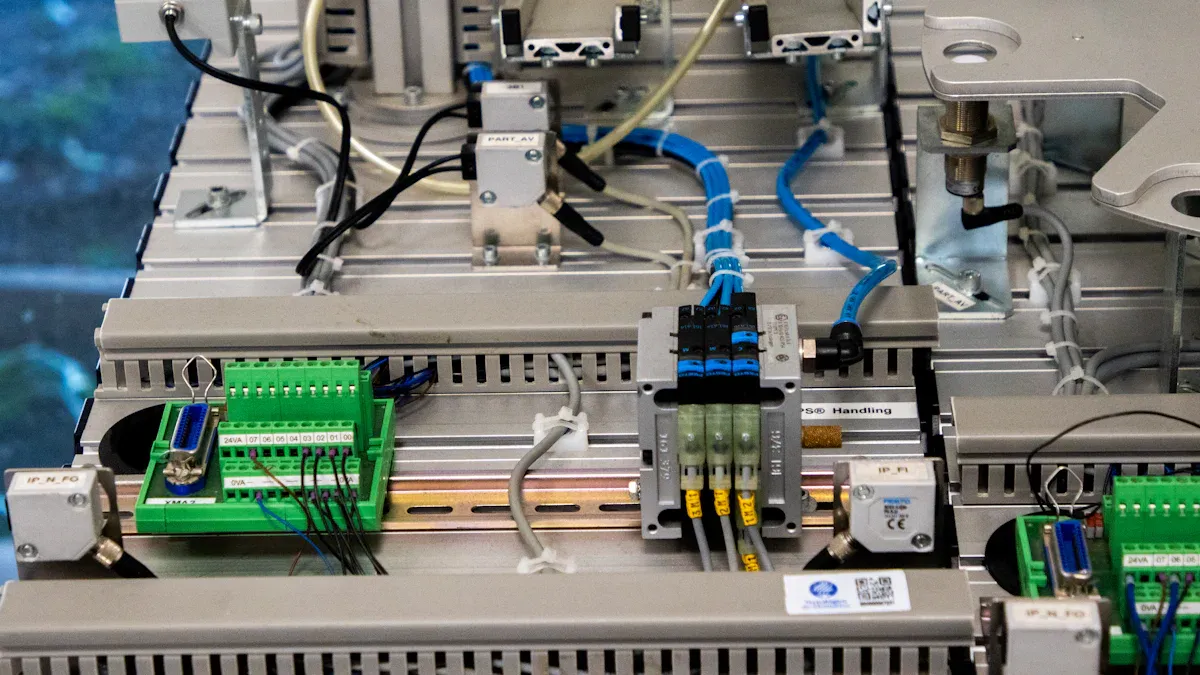

You should know what technology a pcb manufacturer uses. New technology makes your pcb circuit board work better. It also makes the board more accurate. The best manufacturers use many modern machines and tools, such as:

Computer Aided Design (CAD) software with AI for better design accuracy

Computer Numerical Control (CNC) equipment for precise drilling and etching

PCB printing and imaging machines that work with little human help

Wet process equipment for cleaning and preparing boards

Multi-layer presses for making complex boards

Surface finishing machines for strong and safe boards

Automated testing systems to check every pcb assembly

Laser Direct Imaging (LDI) for sharp circuit outlines

High-Density Interconnect (HDI) technology for more connections in less space

These machines help a pcb manufacturer make simple and advanced boards. They can also make flexible and rigid-flex boards.

A good pcb assembly manufacturer does more than just make boards. You should pick a partner who offers many services. This saves you time and helps you avoid mistakes. Here are some things top suppliers do:

Service Type | Description |

|---|---|

Design | Help with custom pcb design for your needs |

Assembly | Skilled workers build and test your pcb assembly |

Testing | Full testing to make sure every board works well |

Procurement Assistance | Support in finding and buying the right parts for your project |

Many suppliers also help with contract manufacturing and finding parts. This makes your project easier from start to finish.

Xinrongxing is different because they use new technology and offer many services. You can order small amounts for testing or big amounts for large projects. Xinrongxing uses prototyping to help you save money on small orders. For big jobs, they use machines and check quality carefully. Their team helps with design, pcb assembly, and finding the right parts. Xinrongxing’s flexible way means you get what you need, whether it is one pcb or a full pcb assembly for a big device.

You want your pcb circuit board to work every time. That is why you should pick a pcb manufacturer with strong quality checks. These steps help find mistakes before they get worse. Good quality control makes sure each pcb and pcb assembly fits your needs. Here are some common quality control steps you should know:

Quality Control Measure | Description |

|---|---|

In-Circuit Testing (ICT) | Tests for open or short circuits and checks how well the circuits work. |

Flying Probe Test | Finds loose connections using a probe that follows a computer design grid. |

Functional Test | Makes sure the pcb works under real test equipment and meets safety standards. |

Automated Optical Inspection (AOI) | Uses cameras to spot missing parts or soldering problems. |

X-Ray Inspection | Looks inside the pcb to find hidden shorts or open circuits. |

Electrical Testing | Powers up the board and checks if signals match what you expect. |

Visual Inspection | Checks for scratches, misalignment, or other physical damage. |

Xinrongxing uses these quality control steps at every stage. You get a pcb assembly that works right the first time.

Certifications show that a pcb manufacturer cares about quality. When you see these certificates, you know the company follows strict rules. Here are some important certifications in the pcb industry:

Certification | Description |

|---|---|

ISO 9001:2015 | Quality management system standard |

UL Listing | Safety and reliability in pcb design and making |

RoHS2.0 | Limits hazardous substances for safer products |

CQC | Shows the product meets China’s quality rules |

Xinrongxing has ISO 9001:2015, UL, RoHS2.0, and CQC certifications. These awards prove they care about high standards and safe pcb circuit board making.

You want your pcb to meet global rules. Testing makes sure your pcb assembly is safe and reliable. Top companies follow rules from groups like ISO and IPC. These groups set the bar for quality and performance. Here are some standards you should look for:

ISO: Checks that the pcb manufacturer meets quality rules.

IPC: Sets rules for how pcbs should work and last.

UL: Makes sure the pcb is safe to use.

RoHS: Keeps harmful chemicals out of your pcb.

MIL: Sets tough rules for military pcbs.

Xinrongxing tests every pcb to meet these standards. You get a product that works well and lasts longer.

Tip: Always ask your supplier about their quality checks and certifications. This helps you avoid problems later.

You need to be able to change your design when starting a pcb project. Customization lets you make your pcb circuit board fit your needs. You can pick the size, shape, and layout you want. Many customers want special features to make their products unique. You can choose from different options to help your board work better and look nicer.

Customization Option | Description |

|---|---|

Solder Mask Colors | You can pick colors like red, blue, white, black, or yellow. This helps with style and finding boards. |

Material Selection | You choose materials that change how your pcb works and how long it lasts. |

Thickness Options | You pick the thickness that matches your design. |

Surface Finishing | You choose finishes that make your board work better and look good. |

These choices help you make a pcb assembly that fits your project. You get more say in how your product looks and works.

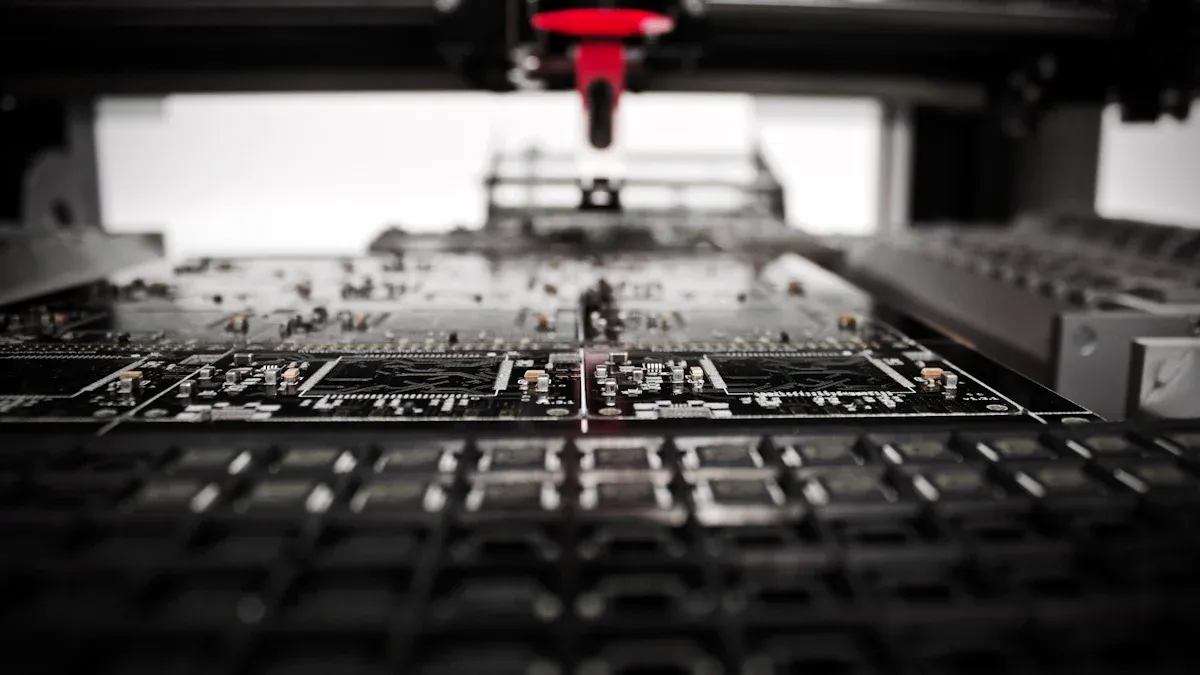

Prototyping helps you finish your project faster. You can test your design quickly and spot problems early. Fast prototyping lets you fix your pcb assembly before making lots of boards. You save time and money by fixing mistakes early. Quick prototyping helps you go from idea to making products faster. You can meet what the market wants and sell your product sooner.

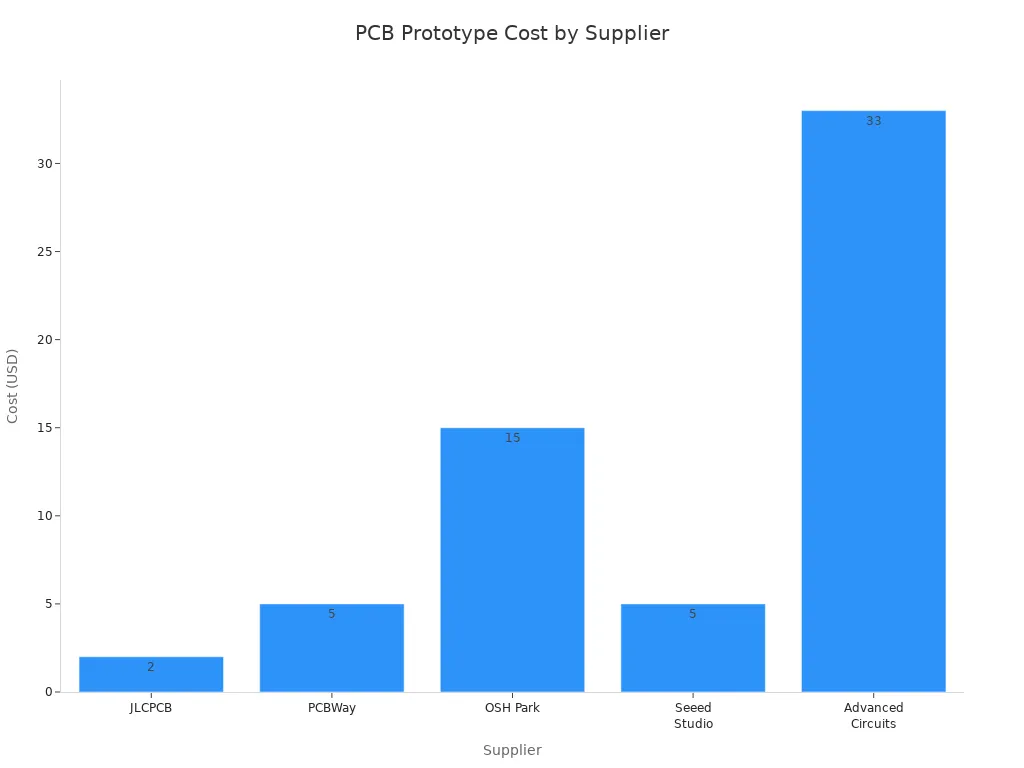

You also want to know how much prototyping costs. The best suppliers have different prices for pcb prototypes. Here is a table that shows the average price for a 2-layer pcb prototype:

Supplier | Cost for 2-layer PCB Prototype |

|---|---|

JLCPCB | Starts at $2 for 10 boards |

PCBWay | Starts at $5 for 10 boards |

OSH Park | About $5 per square inch (min 3 copies) |

Seeed Studio | Starts at $5 for 10 boards |

Advanced Circuits | Starts at around $33 for 2 boards |

Tip: Ask your supplier about how fast and how much prototyping costs. Fast service helps you finish your design and pcb assembly on time.

Xinrongxing gives you lots of ways to change your pcb assembly. You can ask for special sizes, shapes, and layouts. Their team helps with OEM and ODM projects, so your pcb matches your brand and product. Xinrongxing uses new design tools to help you make the best pcb circuit board for your needs. You can order prototypes to test your design before making many boards. Their experts help you at every step, from design to the final pcb assembly. You get fast prototyping, easy customization, and strong help for your project.

It is important to know how suppliers set prices. The price changes if you order more or fewer pcb circuit boards. If you buy only a few boards, each one costs more. This is because setup and tooling fees are split between fewer boards. If you buy many boards, the price for each board goes down. For example, a 4-layer pcb might cost $10 each for 10 boards. But if you buy 1,000 boards, each one might cost only $2. Suppliers also add costs for materials, labor, and special features. Always ask for a list of these costs before you order.

Small orders cost more for each pcb because of setup and tooling.

Big orders cost less for each pcb since fees are shared.

Extra features, like more layers or controlled impedance, make pcbs cost more.

You want to get good value for your money. Pick suppliers who give high quality at a fair price. Do not pick the cheapest if it means poor quality. Good suppliers use strong materials and smart ways to make pcbs. This helps you avoid problems with your pcb circuit board. Xinrongxing offers fair prices and checks quality carefully. Their team helps you use your money wisely. You can trust their products to work well and last a long time.

Tip: Always look at both cost and quality from different suppliers. This helps you find the best choice for your project.

Clear quotes help you see all the costs. Some suppliers hide setup, stencil, or testing fees to make prices look lower. You should check every quote for extra charges. Here is a table that shows common hidden fees:

Hidden Fee | Description |

|---|---|

Setup Costs | Sometimes left out to make quotes look cheaper. |

Stencils | Often not included, so you pay more later. |

Testing | Not in first quote, but adds to final cost. |

Minimum Trace/Space | More exact designs cost more to make. |

Controlled Impedance | Needed for signals, costs more to design and test. |

Drill Count & Hole Size | More small holes take longer and cost more. |

Panelization Efficiency | Smart layouts make each board cost less. |

When prices are clear, you can trust your supplier more. You can plan your budget better when you know all the costs. Xinrongxing gives quotes that show every part of the process. Their honesty helps you avoid surprises and plan well. Happy customers come back because they trust Xinrongxing’s prices and cost structure.

You need to know how long it takes to get your pcb order. This is called the lead time. Most top suppliers offer a lead time of about 20 working days. Some can finish your order faster with quick-turn options. These options can shorten the lead time to between 1 and 15 working days, depending on your project. If you plan your order well, you can avoid delays. You should always ask your supplier about the lead time before you place your order. Changes in engineering requirements or missing parts can make the lead time longer. Make sure your design is ready and your parts are in stock to keep the lead time short.

On-time delivery is very important for your project. You want your pcb to arrive when you expect it. Leading manufacturers have an on-time delivery rate of over 95%. This means most orders reach customers on schedule. You can help ensure on-time delivery by sending complete files and clear instructions. Delays often happen because of:

Changes in engineering requirements

Out-of-stock or obsolete parts

Errors in manufacturing files

Incomplete parts kits

If you work closely with your supplier, you can avoid these problems. Xinrongxing has a strong record for on-time delivery. Their team checks every order and keeps you updated.

Good logistics support helps your pcb arrive safely and on time. Xinrongxing uses ESD-safe packaging to protect your boards from static electricity. Their handlers wear wrist straps to prevent static discharge. They also keep boards away from high-static areas. Moisture can damage pcbs during shipping. Xinrongxing uses moisture control methods to stop corrosion and defects. Their logistics team tracks every shipment and solves problems quickly. You get reliable delivery and strong support from start to finish.

Tip: Always ask your supplier about their packaging and shipping process. Safe handling and fast shipping protect your investment.

Having good customer support is very important for your project. You need a supplier who listens and helps you fast. If the team answers your questions, you can avoid mistakes. Clear feedback from your supplier helps you finish your project on time.

Talking with your supplier helps you share what you need. You can tell them your design ideas and get advice. When you talk to engineers, you can find errors early. This stops small problems from getting bigger. Studies show that 30% of PCB prototypes fail because people do not talk enough. If you keep in touch, you get answers faster and better results. For example, the support team can find problems like wrong trace width during design checks. This helps you avoid signal problems and keeps your project moving.

Tip: Always ask questions and give updates to your supplier. Good communication helps you finish your project faster and with fewer problems.

You need help from experts when you design and build your PCB. A strong support team gives advice about materials and layout. You can ask for help with testing or engineering support. Xinrongxing’s team helps you solve design problems and pick the best options. They guide you through certifications and quality checks. You get answers about supply chain and factory needs.

Here are important things to look for in PCB supplier support:

Customer empowerment

Reduced costs

Manufacturing costs

Timescales

Ability to work together

Materials sourcing

Board testing

Certifications

Factory facilities

Engineering support

Quality assurance systems

Supply chain management

After you get your PCB, you might need more help. Good after-sales service means you get support even after delivery. Xinrongxing helps with troubleshooting, repairs, and upgrades. Their team answers your questions and fixes problems fast. You can ask for advice on using your PCB in new projects. This support builds trust and helps you do well in future projects.

Note: Good customer support and clear communication make your experience easy from start to finish. You feel safe knowing your supplier helps you every step of the way.

Picking the right PCB supplier helps your project do well. Here is a checklist to help you choose:

Criteria | Description |

|---|---|

Manufacturing Capabilities | Can the supplier make boards for your project? |

Quality Control | Do they use rules like ISO, UL, and RoHS? |

Cost | Are the prices good for what you get? |

Lead Time | Will your boards arrive when you need them? |

Do they help you and answer questions fast? | |

Certifications | Do they have papers that show they make safe boards? |

If you use these steps, you make better choices. Xinrongxing is ready to help with good service and strong quality. You help your project win when you pick the right supplier.

You should check the supplier’s experience and quality control. A good supplier uses strong materials and tests every board. This helps your project work well.

Most suppliers finish orders in 1 to 20 working days. Xinrongxing offers quick-turn options for urgent needs. You can ask for the fastest delivery when you order.

Yes! You can ask for special shapes, sizes, or layouts. Xinrongxing helps you design a PCB that fits your project. You get support from start to finish.

Look for ISO 9001, UL, and RoHS certifications. These show the supplier follows safety and quality rules. Xinrongxing has all these certifications.

You can contact Xinrongxing’s support team by phone or email. They answer questions and help you solve problems quickly.

Tip: Always keep your supplier’s contact details handy for fast help.