close

Choose Your Site

Global

Social Media

Views: 0 Author: Site Editor Publish Time: 2025-09-18 Origin: Site

A PCB circuit board is just a plain board. It is the base for electronic devices. A PCBA is a PCB with all parts put on and soldered. Knowing this difference helps you plan design, costs, and buying. PCBAs are good for complex and strong devices. PCBs are best for simple or test projects. Xinrongxing explains these words to help you choose well.

The world market for PCB and PCBA is still growing, as you can see below:

Year | PCB Market Size (USD Billion) | PCB & PCBA Market Size (USD Million) | HDI Segment (USD Billion) | PCBA Assembly Segment (USD Billion) |

|---|---|---|---|---|

2023 | N/A | N/A | >90 | |

2024 | 75.9 - 91.8 | 80,675.4 | >19.5 | N/A |

2033 | N/A | 107,327.29 | N/A | N/A |

Know the difference: A PCB is just a plain board. A PCBA has all its parts attached. Knowing this helps you plan your project.

Make good choices: Use PCBs when you want to test ideas. Use PCBAs for finished products that need to work, like phones and home devices.

Quality is important: Always use the right rules and steps when you design and build. This keeps your electronics safe and working well.

Get expert help: Xinrongxing gives many services, from making PCBs to putting them together. Their skills can make your project better.

Think about cost and time: PCBs cost less and are faster to make than PCBAs. Plan your money and time so your project goes well.

You often see "pcb circuit board" in electronics. A pcb is a flat board made from fiberglass. It has copper lines and pads. These lines connect different spots on the board. The main job of a pcb is to hold and link electronic parts. A bare pcb does not have any parts on it. It is just the base for building circuits.

Official rules like IPC-2221 and IPC-6012 help you design and check a printed circuit board. These rules make sure your pcb is safe and works well. IPC-A-610 gives rules for soldering and putting parts on, so you get good results.

Here is a table that shows how a pcb and a pcba are different:

Aspect | PCB (Printed Circuit Board) | PCBA (Printed Circuit Board Assembly) |

|---|---|---|

Definition | Bare, unpopulated board providing electrical connections | Populated PCB with electronic components, forming a functional circuit |

Function | Mechanical support and electrical pathways for components | Performs a specific electronic function |

Components | None (empty board) | All necessary electronic components (resistors, capacitors, ICs, etc.) |

Appearance | Flat board with conductive tracks, pads, and holes | Board with various electronic components attached |

Manufacturing | Etching copper layers onto a substrate; applying solder mask | Placing and soldering components onto the PCB (SMT, through-hole) |

Testing | Continuity and short testing of copper traces | Comprehensive testing (ICT, functional testing) to ensure proper operation |

Stage | Foundation/Base | Completed/Functional Circuit |

Applications | Used in early design stages, prototyping, and circuit validation | Used in final products like smartphones, computers, and industrial electronics |

A pcba is a pcb with all the parts put on and soldered. You use a pcba when you need a working circuit. The assembly process adds resistors, capacitors, chips, and other parts to the board. This makes the pcb able to do things, like power a phone or run a machine.

You test a pcba to make sure it works right. You check each part and connection. Industry rules like IPC-A-610 and ISO 9001:2015 help you keep quality high. RoHS and UL certifications make sure your pcba is safe and good for the environment.

Some people think rigid and flexible circuits use the same rules. Others think looks matter more than how it works. Some believe you can put parts anywhere on the board. These ideas are wrong. You must follow design rules and place parts carefully to stop problems.

Tip: Always check the rules and guides before you design or build a pcb or pcba. This helps you avoid mistakes and makes sure your circuit board works well.

Xinrongxing gives you both pcb and pcba help you get advice from experts who know how to make good boards and assemblies. Xinrongxing offers full services, from making the bare pcb to putting on all the parts. You can use their help for electronics, cars, medical, and industrial products. Xinrongxing uses advanced SMT and through-hole methods. You get strong soldering, good part placement, and full testing for every pcba. The company follows IPC rules and supports RoHS. You can trust Xinrongxing for good parts and strict checks.

You get full pcba services, including assembly and testing.

Xinrongxing can handle small or big orders.

The company gets good parts from trusted suppliers.

You benefit from strict IPC rules and support for BGA/QFN assembly.

You can count on Xinrongxing for both pcb circuit board and pcba needs. Their skill and focus on quality help you do well in your electronics projects.

You have many types of pcb to pick from. Each type works for different jobs. Xinrongxing sells single-sided, double-sided, and multi-layer printed circuit boards.

Single-sided pcb: This board has copper tracks on one side only. You use it for easy things like calculators or remote controls. Single-sided boards cost less and are simple to make.

Double-sided pcb: This board has copper tracks on both sides. You can link parts on both sides with holes called vias. Double-sided boards are good for harder electronics. In 2023, double-sided pcbs were over 36% of the world’s car pcb market. You find them in lights and control units.

Multi-layer pcb: This board stacks many copper and insulation layers. You use multi-layer boards for smart devices like computers and car systems. These boards let you fit more circuits in small spaces. Multi-layer pcbs are wanted more as tech gets harder.

Note: Multi-layer printed circuit boards are important for new things like electric cars and smart gadgets.

Here is a table that shows the main parts of a printed circuit board and how they change how it works:

Component | Function | Impact on Performance |

|---|---|---|

Substrate Materials | Give strength and insulation | Decide how stable and reliable it is |

Copper Layers | Make signal paths and carry current | Change power and signal quality |

Dielectric Layers | Keep conductive layers apart and control impedance | Affect signal flow and how well it works |

You must choose the best materials for your pcb. Xinrongxing uses FR-4 and FR-1 for its printed circuit boards.

FR-4: This material is strong and insulates well. It handles heat and does not soak up much water. FR-4 is best for most new pcb circuit board designs.

FR-1: This material costs less and gives basic insulation. You use FR-1 for easy, low-power jobs.

Here is a quick comparison:

Material | Advantages | Disadvantages |

|---|---|---|

FR-4 | Strong, insulates well, handles heat, low water absorption | Costs more, not very flexible |

FR-1 | Cheap, basic insulation | Weak with heat, not very strong |

Xinrongxing makes sure every pcb follows ROHS rules. This means your printed circuit board is safe for nature and has no bad stuff. You get good quality and strong boards every time you order.

You begin by getting the pcb ready for assembly. First, you put solder paste on the pcb circuit board. A stencil and machines help put the paste in the right places. This step stops mistakes when you solder later. Next, you add the parts to the pcb. Pick-and-place machines put each part where it should go. You must check that every part matches the pads. After this, the board goes into a reflow oven. The oven’s heat melts the solder paste. This connects the parts to the pcb. You need to watch the heat to keep the board safe. After soldering, you look at the printed circuit board assembly. Machines check for problems like parts in the wrong spot or short circuits. People also check by hand to find anything the machines miss. The last thing you do is test the board. You use in-circuit or functional testing to make sure the pcba works right.

Here is a table that shows the main steps in the pcb assembly process:

Step | Process Description | Best Practice |

|---|---|---|

Solder Paste Application | A stencil is used to apply solder paste to the designated areas of the board. | Use automated machinery for even and accurate paste application to avoid soldering defects. |

Component Placement | Components are placed directly onto the solder-pasted board using pick-and-place machines. | Ensure components are aligned accurately to avoid defects during soldering. |

Reflow Soldering | The board passes through a reflow oven to melt the solder paste for solid connections. | Monitor the temperature profile to prevent overheating or insufficient heat. |

Inspection and Quality Control | Automated systems check for soldering issues like misalignment or short circuits. | Utilize both automated and manual inspection processes to meet quality standards. |

Testing | Functional testing checks for shorts, open circuits, and proper functionality. | Perform In-Circuit Testing (ICT) or Functional Circuit Testing (FCT) before shipment. |

Xinrongxing uses new machines for every pcb assembly. You get strong quality checks at every step. The team checks the first board and keeps checking as they work. Machines like optical and X-ray tools help find problems. You also get reports about how many boards pass and fail. Xinrongxing tests every printed circuit board assembly to make sure it works well.

Many kinds of parts go into a pcba. The most common are surface mount and through-hole parts. Surface mount parts are small and sit on top of the pcb. You need special machines to put them in place. This makes the job harder but lets you make smaller and faster things. Through-hole parts have wires that go through holes in the pcb. These parts are bigger and easy to put in by hand. They are good for strong connections and bigger devices. Some printed circuit board assembly jobs use both kinds of parts. This mixed way lets you make hard circuits with lots of features.

Here is a table that explains the main types of components and how they affect the pcb assembly process:

Component Type | Description | Influence on Assembly Complexity |

|---|---|---|

Surface Mount (SMT) | Involves placing small devices on the PCB, requiring precise handling. | Increases complexity due to size and careful positioning requirements. |

Through-Hole (THT) | Traditional method for larger components with terminals passing through holes. | Allows for larger components but can complicate assembly due to size. |

Mixed Technology | Combines SMT and THT for complex circuits. | Requires careful sequencing to manage assembly and soldering. |

Xinrongxing checks every part before using it. You get good parts and strong connections. The company uses both machines and people to check for problems. They also test boards in tough conditions to make sure they last. Xinrongxing fixes any problems fast with a closed-loop system. You can trust their pcb assembly for your electronics projects.

You use a pcb as the base for your electronic projects. The pcb circuit board connects all the parts in your design. It gives you a way to test and change your ideas before you finish your product. When you need a working device, you use a pcba. The pcba has all the electronic parts placed and soldered onto the board. This makes the circuit board ready to power devices like smartphones, laptops, and home appliances.

In real projects, you often start with a pcb for prototyping. You can check your design and make changes. When you move to mass production, you use a pcba. The pcba gives your device the functions it needs. For example, Xinrongxing helps you with both steps. You can order a single pcb for testing or a full pcba for your final product.

Here is a table showing how different devices use pcb and pcba:

Device Type | Description |

|---|---|

Smartphones and tablets | Use multi-layer pcbas for compact designs with many features. |

Laptops and desktops | Need complex pcbas for motherboards and graphics cards. |

Wearable devices | Use flexible pcbas for small and light products. |

Home appliances | Rely on pcbas for control and automation in washing machines and smart thermostats. |

You also see pcbas in computers, cameras, audio equipment, and gaming consoles. Each device needs a different type of manufacturing and assembly.

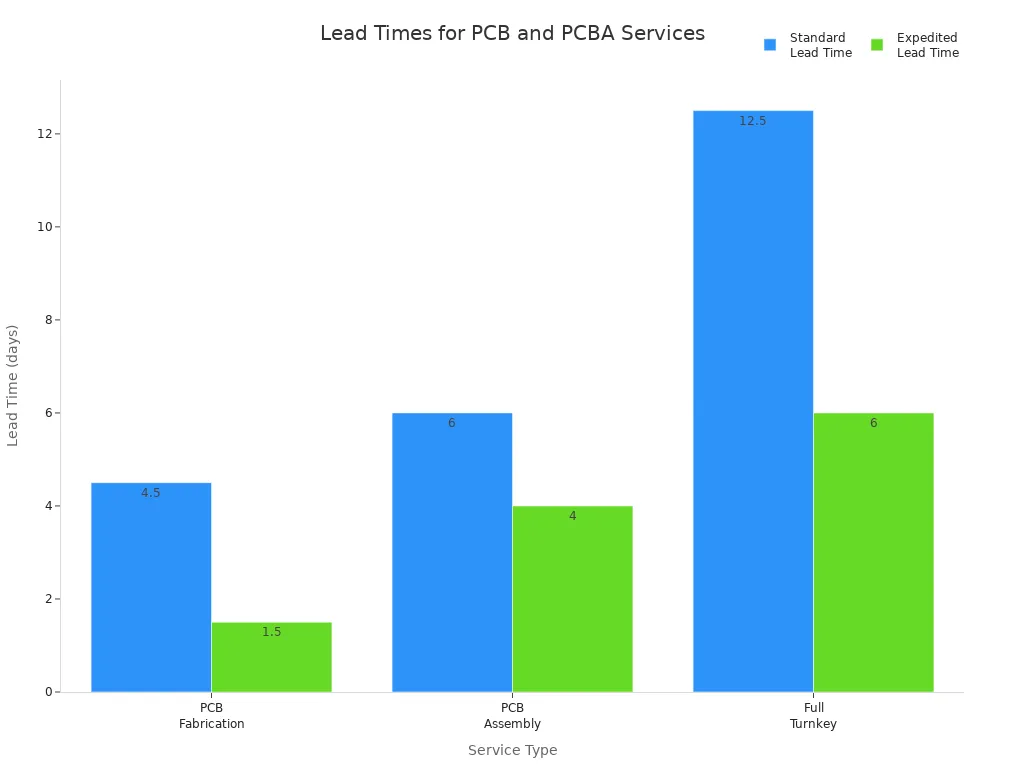

When you plan your project, you must think about cost and time. Making a pcb costs less than making a pcba. The main cost for a pcb comes from the bare board fabrication. For a pcba, you pay for the board, the parts, and the assembly work. The price of components can be 50–90% of the total pcba cost. Labor and testing add more to the final price.

PCB manufacturing costs include making the bare board.

PCBA costs include placing and soldering parts, plus testing.

More complex boards and more parts mean higher costs.

Lead time is also important. You can get a pcb in 4-5 days with standard service. If you need it faster, some suppliers offer 24-48 hour delivery. For a pcba, standard assembly takes 5-7 days. Full turnkey service, which includes both pcb manufacturing and assembly, can take 10-15 days. Expedited options are available for urgent projects.

When you choose between pcb and pcba, you should look at quality control, lead time, and the range of services. Xinrongxing offers strong quality checks, fast delivery, and full support for both pcb and pcba manufacturing. You can trust Xinrongxing to help you meet your project goals.

Xinrongxing helps many industries with pcb and PCBA. They work with companies that want high standards and new technology. You find Xinrongxing’s pcb products in communication equipment, cars, planes, medical tools, home electronics, and factory systems. Big brands trust Xinrongxing for strong pcb boards. Their team knows how to handle hard pcb jobs for each field. Car electronics need pcb designs that can take heat and shaking. Medical tools need pcb assemblies with careful safety and quality checks. Xinrongxing changes its pcb process to match these needs.

Xinrongxing gives you strong quality checks for your pcb projects. The company has important certificates that prove it cares about safety and quality.

Certification | Description |

|---|---|

ISO 9001 | Quality management systems |

IATF 16949 | Automotive quality management |

REACH | Chemical safety regulations |

RoHS | Restriction of hazardous substances |

UL | Underwriters Laboratories safety standards |

Xinrongxing makes pcb and PCBA solutions just for you. You can ask for special things like impedance control, gold fingers, or a certain stack-up. Xinrongxing looks at your design files early and gives you a quote fast. If your pcb design is hard, you can send assembly drawings as a PDF for clear steps.

You get full help from Xinrongxing’s team. They offer:

Service Type | Description |

|---|---|

PCB Assembly (PCBA) Services | SMT, PTH, COB, AOI, X-RAY, and more. |

One-Stop Service | Schematic design, pcb making, assembly, and injection molding. |

Fast Response | Replies within two hours, quotes in 24 hours, and fast prototypes. |

Quality Assurance | Professional team and systems to ensure pcb quality. |

Professional Replace-Solution | Sourcing for high-quality, cost-effective components. |

No MOQ | Order as few as one pcb or PCBA. |

Full Suite of Design Services | From schematic to delivery, including sourcing and assembly. |

You can trust Xinrongxing to give you pcb products that fit your project. Their focus on quality, custom choices, and service helps you do well in any industry.

You should know how a PCB and a PCBA are different for any electronics project. The table below explains the main idea:

Term | Definition |

|---|---|

PCB | A Printed Circuit Board is the base with copper lines on a board that does not conduct electricity. |

PCBA | A Printed Circuit Board Assembly is when the PCB has all its parts put on and soldered, so it can work. |

A PCB is just a board with no parts.

A PCBA has all its parts attached and is ready to use.

If you know these words, you can talk about what your project needs. You can plan how things are made and how to test them. You can make sure everything works well by knowing each step. Xinrongxing helps you with making and testing, so your project does well. You can ask Xinrongxing for help with every part of making and testing.

A PCB is the base for your electronics. A PCBA has all the parts put on it. You use a PCB when you design and test ideas. You use a PCBA when you want a working device for many people.

PCB design helps you plan how things will work. Good design keeps your circuits safe and working well. It makes sure your project does what you want. It also saves time and money when you make lots of boards.

Xinrongxing uses new machines to make pcbs. They help you with design, finding parts, and putting them on. The team checks each step to keep quality high. You can trust Xinrongxing to make good electronics for big orders.

You use FR-4 and FR-1 to make pcbs. These materials help your boards last a long time. Good materials make your design strong. Xinrongxing always uses safe and trusted materials for every project.