close

Choose Your Site

Global

Social Media

Views: 0 Author: Site Editor Publish Time: 2025-09-22 Origin: Site

Do you know why a PCB circuit board glossary matters? Misunderstanding key terms can cause design mistakes and costly delays. Knowing the right words speeds up work between engineers, buyers, and manufacturers. In this article, you will learn clear definitions and explanations of essential PCB terms.

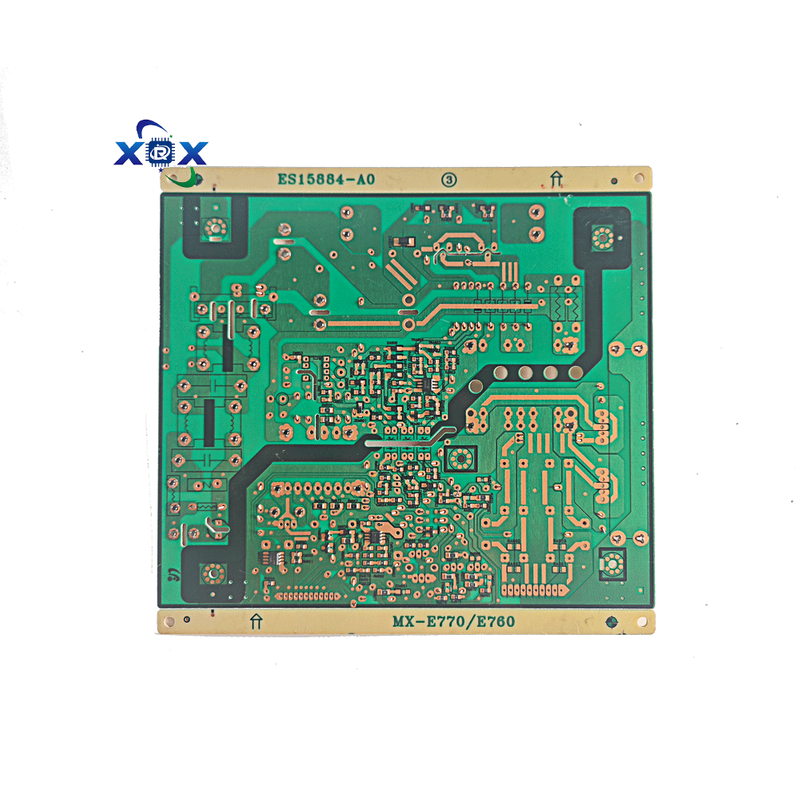

A PCB circuit board is the foundation of nearly every electronic device. It connects components using copper traces, pads, and vias. These conductive paths replace bulky wires, allowing compact and reliable designs. PCBs can be single-sided, double-sided, or multilayer, depending on complexity. They are built from base materials like FR4 fiberglass, ceramics, or even metal cores for heat management.

PCBs are essential because they combine mechanical support and electrical pathways. From smartphones to industrial controls, they make complex circuits practical, durable, and scalable for mass production.

The term PCB circuit board often overlaps with other names. In some industries, it is called a printed wiring board (PWB) or simply a board. In computing, the main board in a device is known as a motherboard. For expansion modules, you may see daughter boards or cards.

While these terms are used interchangeably, they may highlight different functions. For example, “motherboard” emphasizes system integration, while "card" suggests modularity. Recognizing these synonyms avoids confusion when sourcing components or reviewing technical drawings.

Clear terminology speeds collaboration between engineers, manufacturers, and buyers. A shared understanding reduces costly mistakes in design, fabrication, or assembly. For instance, misinterpreting terms like annular ring or plated-through hole can lead to design rule violations or production errors.

In quality control, standardized terms also support compliance with IPC and UL standards. This ensures consistency across suppliers and global production sites. For purchasing teams, correct usage helps specify requirements and compare vendor capabilities.

The base of a PCB circuit board is its substrate. FR4, a fiberglass-reinforced epoxy, is the most common choice. It offers strength, insulation, and flame resistance. Ceramic substrates are used where high heat transfer and durability are needed, such as aerospace or automotive systems. Metal core PCBs rely on aluminum or copper to improve heat dissipation, making them suitable for LED lighting and power electronics.

Different substrates change cost, performance, and application. While FR4 fits consumer electronics, ceramic boards serve critical industries that demand stable performance at extreme temperatures.

Copper layers form the conductive pathways of a board. Their thickness is described as "copper weight", measured in ounces per square foot. For example, 1 oz copper equals about 35 micrometers thick. Heavier copper is used in power devices where current capacity matters.

A board's layer count defines its stackup. Single-layer boards are inexpensive but limited. Double-sided boards provide more routing options. Multilayer boards, which can exceed 8 or more layers, allow compact designs and higher signal integrity. Stackup design also impacts impedance control, cost, and manufacturability.

Term | Meaning | Use Case |

1 oz copper | Standard thickness | Consumer electronics |

2–3 oz copper | Heavy copper | Power converters |

4+ layers | Multilayer stackup | Smartphones, servers |

The solder mask is a protective polymer layer applied over copper. It prevents oxidation, reduces shorts, and gives the board its color, typically green. Alternative colors like red, blue, and black are also available for branding or visibility.

Silkscreen is the printed layer that shows reference designators, part numbers, or company logos. It supports assembly and troubleshooting. The surface finish, such as HASL, ENIG, or OSP, protects exposed copper pads and improves solderability. Choosing the right finish depends on storage life, cost, and assembly requirements.

Pads are flat copper areas where components are soldered. They may be through-hole or surface-mount types. Tracks are conductive lines connecting pads and components. Their width and spacing directly affect current capacity and signal quality.

Vias create vertical connections between layers. Through-hole vias go from top to bottom, blind vias connect outer to inner layers, and buried vias only link inner layers. Tented vias are covered with solder mask for insulation or protection. Using the right via type reduces board size but can raise costs.

Note: When sourcing from manufacturers, specify copper weight, stackup, and via type early. This avoids redesigns and ensures accurate quotations.

Designing a PCB circuit board begins with CAD software. CAD (Computer-Aided Design) lets engineers create board layouts, simulate placement, and adjust routing before manufacturing. CAE (Computer-Aided Engineering) tools add schematic capture, analysis, and visualization. These ensure circuits behave as intended.

CAM (Computer-Aided Manufacturing) bridges design and production. CAM files provide machine-readable instructions, guiding fabrication and assembly processes. Together, CAD, CAE, and CAM reduce errors and make collaboration between designers and manufacturers more efficient.

Gerber files are the universal language of PCB production. They define copper layers, solder mask, silkscreen, and more. NC Drill files specify hole locations and sizes for vias, pads, and mounting points. Without accurate drill data, alignment and conductivity issues can occur.

Fabrication drawings complement these files. They show dimensions, materials, and tolerances, providing manufacturers with context beyond raw coordinates. A complete design package includes Gerber, drill, and fab drawings for clarity.

Document Type | Purpose | Critical Use |

Gerber File | Defines copper and layers | Guides photoplotting |

NC Drill | Lists drill data | Controls hole placement |

Fab Drawing | Notes dimensions, materials | Ensures production accuracy |

Assembly drawings direct how components are placed and soldered. They show reference designators—alphanumeric codes like R1 or C5—that link physical parts to schematics. These markings make it easier to identify parts during assembly and inspection.

Component libraries inside CAD tools store footprints and parameters. A well-maintained library reduces mistakes, ensures standardization, and accelerates new designs. Reusing accurate footprints saves time while keeping compatibility with manufacturing lines.

Design Rule Checks (DRC) verify whether a PCB layout meets design standards. It checks spacing, trace width, drill sizes, and clearances. Running DRC before sending files prevents costly rework.

Netlists describe the logical connections between components. They ensure the physical layout matches the intended schematic. If mismatches appear, they must be corrected before fabrication. Together, DRC and netlists safeguard design integrity.

Every PCB circuit board combines active and passive parts. Active components, such as transistors, diodes, and ICs, control current flow or amplify signals. Passive components like resistors, capacitors, and inductors store or regulate energy but do not amplify.

Design balance is critical. Active parts provide functionality, while passive parts ensure stability and protection. For example, a capacitor smooths voltage ripple while an IC manages processing tasks.

Through-hole technology involves inserting leads into drilled holes and soldering them to pads. Dual in-line packages (DIP) are common for ICs. Headers and connectors also use through-hole pins for strength.

This method offers robust mechanical stability, making it popular in high-stress environments like industrial machines. However, it requires more board space and increases drilling costs.

Package Type | Description | Common Use |

DIP | Two rows of pins | ICs, logic chips |

Header | Pin strips | Expansion modules |

Connector | Plug/receptacle | Cable interfaces |

Surface Mount Technology (SMT) solders components directly on board surfaces. Surface Mount Devices (SMDs) are compact, support automation, and reduce board size.

BGA (Ball Grid Array) packages use solder balls instead of pins, ideal for high-density ICs. QFP (Quad Flat Pack) devices have leads on all sides, suited for microcontrollers and processors. SMT dominates consumer electronics due to speed, cost efficiency, and high component density.

A PCB circuit board has two functional sides. The component side, often called the top, holds most visible parts. The solder side, usually the bottom, contains solder joints. In double-sided or multilayer boards, both sides may carry components.

Identifying sides is important during assembly and inspection. Clear silkscreen markings reduce errors in orientation and placement.

Manufacturers rarely build a single PCB circuit board at once. Instead, they panelize multiple boards into arrays. This approach improves efficiency during soldering and testing. After assembly, panels are separated into individual units using V-scoring or mouse bites.

Panelization also stabilizes smaller boards during production. It allows automated equipment to handle them reliably, reducing defects and scrap.

Pick-and-place machines automatically place components onto boards with precision. Once parts are set, reflow soldering melts solder paste to secure surface mount devices.

For through-hole parts, wave soldering is often used. The board passes over a wave of molten solder, bonding component leads in a single pass. Together, these processes ensure speed and consistency in assembly.

AOI systems capture high-resolution images of each board. They detect defects like misaligned parts, solder bridges, or missing components. This step is vital for multilayer boards where visual inspection is difficult.

Functional testing goes further, confirming that the PCB circuit board performs as intended. It simulates real operating conditions, verifying voltage levels, connectivity, and reliability.

AQL defines the acceptable defect rate in a production batch. It balances cost with quality by setting realistic inspection standards. First article testing, meanwhile, involves producing an initial unit or small lot. Engineers then review it to confirm compliance before mass production.

Both AQL and first article testing reduce risk. They ensure quality issues are caught early, preventing expensive recalls.

Special hole types serve different assembly needs. Press fit holes allow components to snap into place without solder. Countersink holes let flat-head screws sit flush, useful in tight assemblies. Slot holes accommodate connectors or custom-shaped components.

These features enhance functionality but increase fabrication complexity. Careful design ensures they do not compromise board strength.

Conformal coating is a thin protective film applied to finished boards. It shields against moisture, dust, and chemicals. Coatings are common in automotive, aerospace, and outdoor electronics where harsh conditions exist.

Other protective layers include carbon masks or specialized resins. They extend service life and improve long-term reliability of the board.

Process Term | Purpose | Typical Application |

Panelization | Build multiple boards | Small devices |

Reflow | Bond SMD parts | Consumer electronics |

AOI | Detect assembly defects | Multilayer boards |

AQL | Define defect limits | Mass production |

Countersink | Fit flush screws | Compact housings |

Conformal coating | Environmental protection | Automotive, aerospace |

A PCB circuit board may carry analog, digital, or mixed circuits. Analog circuits handle continuous signals, like audio or sensors. Digital circuits process binary signals, ideal for processors and memory.

Designers must separate analog and digital paths. Mixing them without care leads to noise issues. Isolation improves accuracy and ensures stable system performance.

Impedance is resistance to AC signals. Controlled impedance is vital in high-speed boards. Capacitance, meanwhile, is the ability to store energy between conductors. Both parameters affect timing, signal speed, and circuit behavior.

Ground planes stabilize performance. They reduce noise, provide shielding, and act as a return path. Without proper ground design, even well-built boards can fail under load.

Electromagnetic compatibility ensures devices work without disturbing each other. Designers add shielding, filters, and layout strategies to achieve compliance.

Electrostatic discharge (ESD) can damage sensitive parts instantly. Using protective components, grounding, and coatings helps guard against failures. In industries like automotive or medical, EMC and ESD compliance is mandatory.

Signal integrity is about preserving clean signals across the board. Back drilling removes unused via stubs, preventing reflections in high-frequency designs. Fine pitch components allow dense packaging but demand precise routing.

Controlled impedance ensures predictable transmission. It requires careful layer stackup, trace width, and spacing. Poor design causes crosstalk, distortion, or data errors.

High-Density Interconnect (HDI) boards are compact PCB circuit board designs with fine lines, microvias, and thin dielectrics. They support more components in less space, which is critical in smartphones, tablets, and wearables.

HDI reduces signal loss and improves speed. Designers use sequential lamination and stacked vias to achieve high density. Although more expensive to fabricate, it enables powerful, space-saving designs.

Some boards integrate resistors or capacitors directly into layers. These buried resistance boards save surface space and improve signal stability. Embedded components reduce parasitic effects, leading to higher performance in RF or high-speed systems.

This method simplifies assembly by minimizing discrete parts. It also enhances long-term reliability since fewer solder joints can fail.

Rigid-flex boards combine rigid substrates and flexible layers. They allow three-dimensional folding without extra connectors. This reduces weight, saves space, and increases durability in aerospace, medical, and military electronics.

By eliminating bulky interconnects, rigid-flex improves reliability in environments with vibration or limited space. They are widely used in foldable devices and medical implants.

Laser photoplotters produce high-resolution images for manufacturing. They improve accuracy compared to older vector plotters, reducing defects during imaging.

Microvias are tiny vias usually less than 150 micrometers. They connect layers in HDI boards, offering shorter paths and lower inductance. Their use is expanding in 5G, IoT, and miniaturized electronics.

IPC standards define global benchmarks for design, assembly, and inspection. They ensure a PCB circuit board meets consistent quality and reliability. IPC-A-600, for instance, specifies acceptability of PCB fabrication. IPC-A-610 focuses on assembly workmanship.

UL certification validates safety and material performance. UL-listed boards have been tested for flammability, insulation, and durability. Manufacturers use these certifications to reassure clients that their boards are safe and compliant.

RoHS (Restriction of Hazardous Substances) limits materials like lead, mercury, and cadmium. A compliant PCB circuit board uses environmentally safe finishes and solders. This is critical for companies exporting to the EU and other regulated markets.

Other regulations, like REACH, expand oversight to additional chemicals. Adhering to these standards not only ensures market access but also builds brand trust in eco-conscious industries.

Test coupons are small sections of the same panel used for destructive and non-destructive testing. They confirm plating quality, layer alignment, and impedance control. Manufacturers rely on them to validate each batch without sacrificing full boards.

Verification methods may also include X-ray inspection, cross-sectioning, and electrical continuity testing. These ensure the delivered boards meet design intent and customer expectations.

Reliability issues often appear during or after fabrication. Bow and warpage refer to deformation, making assembly difficult. Measling describes small white spots caused by resin-glass separation in laminates.

If not addressed, these defects can weaken a PCB circuit board, reduce yield, and shorten service life. Proper material selection, process control, and storage practices help prevent these problems.

Mastering PCB circuit board terminology improves communication, design, and production efficiency. It helps reduce errors, lowers costs, and ensures compliance with key industry standards. By applying this knowledge, readers can work more effectively with manufacturers and achieve better results in new projects. Dongguan Xinrongxing Technology delivers reliable solutions with advanced features and dedicated services, providing real value to businesses seeking consistent PCB quality and performance.

A: A PCB circuit board is a platform that connects electronic components using copper traces, pads, and vias.

A: Knowing PCB circuit board terminology avoids design errors, speeds production, and ensures compliance with standards.

A: Vias are plated holes in a PCB circuit board that connect layers, including through-hole, blind, and buried types.

A: RoHS compliance ensures a PCB circuit board is manufactured without restricted hazardous substances, making it eco-friendly.